Sulzer Nopon disc diffuser system PIK 300

Sulzer Nopon disc diffuser system PIK 300

Membrane disc diffusers for reliable and energy-efficient fine-bubble aeration of tanks in wastewater treatment plants. Suitable for normal continuous aeration systems as well as where intermittent aeration is required, e.g. biological nutrient removal and SBR processes.

Features

- Self-cleaning EPDM membrane with slits

- Membrane is fixed by a bayonet type screw-on ring

- Sliding ring of antifriction material helps in expansion and contraction of the membrane

- Heavy duty stainless steel ball non-return valve

- ABS Nopon wedge piece fixing to the pipe means that no glue, solvent or welding is needed in assembly

- Sliding ring aids in opening the diffuser for maintenance after many years of operation

- Wedge piece fixing makes it easy to increase, decrease or relocate diffusers when process requirements change

- Applicable to various pipe materials and dimensions

- Inlet air temperature is up to 100°C

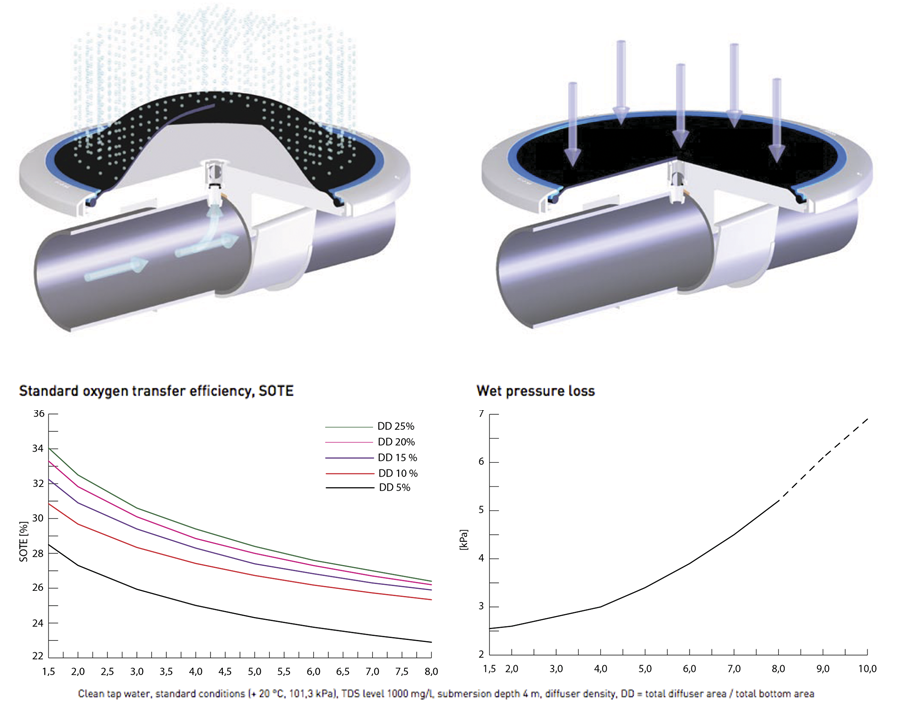

Working principle

The membrane bulges and slits open during aeration by the pressure of compressed air. The main body distributes the air evenly over the entire surface of the membrane. Air is spread into small bubbles, when released through the membrane. When the air flow is turned off, the pressure of the water above presses the membrane disc tightly to the main body closing the small slits on the membrane. The non-return valve with a stainless steel ball pushed down firmly to an o-ring seal inside makes sure that no water enters the pipeline. During normal operation the non-return valve also works as a control orifice.

| |

Description |

Material |

| 1 |

Main body |

PP

(polypropylene)

|

| 2 |

Wedge piece |

PP |

| 3 |

Screw-on ring |

PP |

| 4 |

Sliding ring |

POM

(polyacetal)

|

| 5 |

Membrane disc |

EPDM |

| 6 |

Flat seal |

EPDM или SIL

(silicone)

|

| |

Non-return valve |

|

| 7 |

Valve body |

PP |

| 8 |

Ball |

SS

(stainless steel)

|

| 9 |

O-Ring |

EPDM |

Model range (wedge attachment)

| |

PIK300VD90 |

PIK300D90 |

PIK300SD88,9 |

PIK3004” |

| Pipe |

90mm PVC |

90mmPP |

88,9mm SSNS3”PVC |

NS4”PVC |

| Main body |

PSA300 |

PSA300 |

PSA300 |

PSA300-4 |

| Wedge piece |

PSK90 |

PSK90 |

PSK90 |

PSK4 |

| Slidingring |

PVR300 |

PVR300 |

PVR300 |

PVR300-3 |

| Screw-on ring |

PKR300 |

PKR300 |

PKR300 |

PKR300-3 |

| Membrane disc |

HIK300 |

HIK300 |

HIK300 |

HIK300 |

| Non-return valve |

PTV15L |

PTV15L |

PTV15L |

PTV15-3 |

| Flatseal |

PLT15/4 |

PLT15/4SIL |

PLT15/5 |

PLT15/4 |

Diffuser data

| Design air flow range |

1,5-8,0 m3/h/diffuser (x(+20°C;1013mbar) |

| Diffuser level |

250 mm (xx |

| Air temperature, max |

+ 100°C |

| Max/min assembly depth |

3 - 8 m (optimal) (xxx |

| Diffuser diameter |

336 mm |

| Disc surface area |

0,060 m2 |

| Size of bubbles |

1 - 3 mm |

| Diffuser weight |

0,795 kg |

| Max/min interval, c/c |

1,25 / 0,4 m |

x) When waste water contains chemicals harmful to EPDM or when water temperature is > 30°C or air temperature is close to 80°C, a lower maximum air flow should be used. A peak value of 10 m3/h can be used for max. of 15 min only e.g. for cleaning the membrane. Using air flow less than 1,5 m3/hmust be consulted with Sulzer.

xx) Recommended measure from basin bottom to diffuser top

xxx) Consult Sulzer on depths outside the range