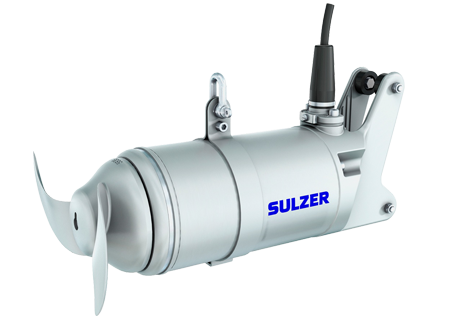

Sulzer submersible mixer XRW 300

Sulzer submersible mixer XRW 300

Compact submersible mixer, designed to achieve an optimum flow pattern in a wide range of mixing and stirring applications, in large tanks and open waters.

Construction

The submersible mixer is designed as a compact, water-pressure-tight unit, including propeller and integrally casted installation bracket for attachment to a square guide tube. The mixer is available in cast iron (EC) and stainless steel (CR) versions.

Motor

Premium Efficiency IE3, three-phase, squirrel-cage motor; 400 V*; 50 Hz; 6-pole. Protection type IP 68, with stator insulation Class H. Start-up: direct on line (DOL). Max. submergence 20 m. * other voltages available

Propeller

Technically optimized, axially operating 2- or 3-blade propeller, designed to achieve high thrust and therefore a high flow capacity in an axial direction.

The propeller is self-cleaning and so ensures vibration-free operation.

Solids deflection ring

The patented solids deflection ring protects the mechanical seal from damage by ingress of solid or fibrous matter.

Bearings

All bearings are lubricated-for-life and maintenance-free, with a calculated lifetime of more than 100,000 h.

Shaft sealing

Sic-Sic mechanical seal at medium side. NBR O-rings and lip seals.

Seal monitoring

DI-system with sensors in the oil**, motor, and cable connection chambers.

Temperature monitoring

Thermal sensors in the stator which open at 140 °C.

Weight (kg)

XRW-PA 15/6 = 62 kg; XRW-PA 29/6 = 82 kg. With flow ring add 11 kg. ** not in Ex version.

Cable

10 m sewage-resistant CSM material, type S1BN8-F. Optional lengths (m): 15, 20, 30, 40, 50.

Options

Explosion-proof version, additional seal (Sic-C) at motor side, flow ring, seals in viton, EMC cable, PTC thermistor in stator, vertical angle adjustment, vortex shield, vibration damper, lifting hoop.

Motor data

| Motor |

PA 15/6 |

PA 29/6 |

| Rated power (kW) |

1,5 |

2,9 |

| Rated current (A) at 400 V |

3,5 |

7,3 |

| Speed (min-1) |

958 |

971 |

| Motor efficiency (%) |

82,5 |

85.6 |

| Power factor |

0,77 |

0.72 |

Mixer performance

| Hydraulic № |

Mixer power PP in kW |

Motor kW |

| 3021 |

0,9 |

1,5 |

| 3022 |

1,2 |

1,5 |

| 3023 |

1,3 |

1,5 |

| 3031 |

1,6 |

2,9 |

| 3032 |

2,1 |

2,9 |

| 3033 |

2,8 |

2,9 |

| 3041* |

0,6 |

1,5 |

| 3042* |

0,7 |

1,5 |

| 3043* |

0,9 |

1,5 |

| 3051* |

1,2 |

2,9 |

| 3052* |

1,5 |

2,9 |

| 3053* |

2,0 |

2,9 |

*with flow ring

Materials

| Part |

EC |

CR |

| Motor housing |

EN-GJL-250 painted |

1.4404 (AISI 316L) |

| Sliding bracket |

EN-GJL-250 painted / polyamide (CF-8M) |

1.4408 / polyamide (CF-8M) |

| Motor shaft |

1.4021 (AISI 420) |

1.4401 (AISI 316) |

| Propeller |

1.4460 (AISI 329) |

1.4460 (AISI 329) |

| Fasteners |

1.4401 (AISI 316) |

1.4401 (AISI 316) |

| Lifting band |

1.4404 (AISI 316L) |

1.4404 (AISI 316L) |