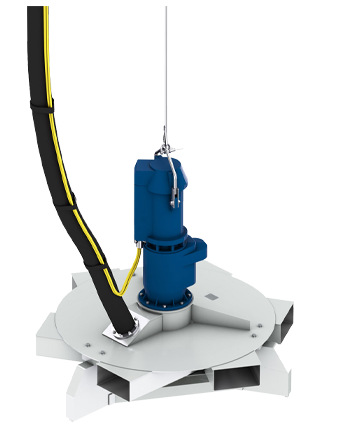

Sulzer Nopon submersible aerator mixer OKI 2000

Sulzer Nopon submersible aerator mixer OKI 2000

The Sulzer Nopon submersible aerator mixer OKI 2000 is a heavy duty machine suitable for applications in continuous and/or intermittent aeration of both municipal and industrial wastewater. It can withstand many harsh types of wastewater with no performance degradation and will tackle intermittent process problems better than most alternatives.

In the OKI compressed air is distributed through a flexible hose down to the machine. Air enters through the stator and is passed on to the rotating rotor. The hollow rotor wings let air out at the tips. As the rotor sucks water from underneath the machine bubbles of air disperse into the water passing the wing tips. The aerated water exits the machine through the stator tubes ensuring even water and air distribution all around the basin. The low speed rotation ensures that flocks are maintained. The turbulence at the tip of the rotor blades enables high oxygen transfer.

Features

- Adjustable oxygen transfer

- Superb pumping capacity

- Good clogging performance

- Good corrosion resistance

- Steady alpha factor

- Lifetime sustainable high aeration efficiency

- Especially suited for heavy duty and intermittent processes

- Easy and quick installation without emptying the tank

- Liftable for easy maintenance

- No air cooling in deep tanks

- Usually delivered complete including suitable air hose, lifting cable and electrical cables making installation safe and easy

The Sulzer Nopon submersible aerator mixer OKI 2000 series is a natural choice for industrial and municipal applications. The high quality gear motor guarantees performance and long lasting operational life minimizing the maintenance costs.

Product range

All 4 OKI 2000 models have the same size rotors, stators and frames. Motor power and gear ratio varies. All models are for both aerating and mixing.

| |

A |

AV |

| 2000 |

C |

15 |

| 2000 |

C |

22 |

| 2000 |

E |

30 |

| 2000 |

E |

27 |

Example: OKI 2000E-37AM

2 design of the stator & rotor

(1 for OKI 1000 series and 2 for OKI 2000 series)

E design of gear

37 rated power of the motor is 37 kW

AM aerator + mixer (mixing without air at high speed)

Components and materials

| |

Description |

Material |

| 1 |

Frame |

Fe37B, epoxy painted |

| 2 |

Rotor |

AISI 316 |

| 3 |

Rotor support |

AISI 316 |

| 4 |

Rotor screw |

AISI 316 |

| 5 |

Stator and stator ducts |

AISI 316 |

| 6 |

Heavy duty shaft seal |

AISI 316 |

| 7 |

Lifting bail |

AISI 316 |

| 8 |

Lifting cable |

AISI 316 |

| 9 |

Drive unit (geared motor) |

Cast iron, epoxy painted |

| 10 |

Cable support |

AISI 316 |

| 11 |

Cables |

Neoprene rubber sheath |

| 12 |

Airlock |

Resin |

| 13 |

Nameplate |

AISI 316 |

| 14 |

Hose flange (with seal) |

AISI 316 |

| 15 |

Hose clamps |

AISI 316 |

| 16 |

Process air hose |

EPDM (reinforced) |

| 17 |

Hose straps |

EPDM |

Technical specification

| |

OKI 2000C-15 AM

|

OKI 2000C-22 AM

|

OKI 2000E-30 AM

|

OKI 2000E-37 AM

|

|

Protection type

|

IP68

|

IP68

|

IP68

|

IP68

|

|

Standard voltage(1

|

400 V / 50 Hz

|

400 V / 50 Hz

|

400 V / 50 Hz

|

400 V / 50 Hz

|

|

Temperature control

|

Thermal

switch 130°C

|

Thermal

switch 130°C

|

Thermal

switch 130°C

|

Thermal

switch 130°C

|

|

Main dimension [mm]

( lenght x depth x height)(2

|

2045x2252x2075

|

2045x2252x2075

|

2045x2252x2195

|

2045x2252x2195

|

|

Unit weight [kg](2(4

|

1930

|

1960

|

2070

|

2070

|

|

Installation depth [m]

|

4-12

|

4-12

|

4-12

|

4-12

|

|

SOTR [kg O2/ h](2(3

|

170

|

220

|

238

|

270

|

|

Air flow rate [m3/ min, 20°C](2(5

|

0-36

|

0-47,2

|

0-53

|

0-60

|

1) Other options for 50 Hz: 230 V, 380 V, 415 V, 500 V, 660 V and 690 V. Also available for 60 Hz: 230 V, 440 V, 460 V and 575 V.

2) Depends on the model

3) At 8 meters

4) Without accessories

5) Depends on installation depth