Sulzer Grinder - 30004T Muffin Monster® - Inline series

The 30004T Muffin Monster sewage grinder is designed to protect pumps and other equipment by grinding down the toughest wastewater solids. Its dual-shafted, slow speed, high-torque design shreds tough solids that typically cause problems in the wastewater treatment process system.

Construction

- Inline pipe configuration

- Pipe flange diameters from 100 mm to 300 mm

- Hardened alloy steel cutters (standard), 120 mm diameter

- Ductile iron unibody housings

- Hardened alloy steel shafts, 50 mm hex

- Mechanical seals with tungsten carbide faces, 10.3 bar maximum dry working pressure

- Easy removable cutter cartridge while inline

Performance

- Flow rates up to 556 m3/hr

Applications

- Sludge lines

- Pump stations

- Private facility discharge to municipal sewer system

- Prison sewage system protection

- Industrial wet waste grinding and maceration

Monster Renew grinder

In place of repairing a worn grinder, choose a Monster Renew unit. Sulzer provides a new, factory-built grinder cartridge to replace the worn grinder cartridge. Remove the motor and reducer from the worn unit, install the motor and reducer on the Monster Renew unit, and install the new assembly in place of the worn unit.

Benefits include:

- Minimizes operational downtime

- Quick turnaround

- All new parts

- Great time to upgrade unit

- Full factory warranty on the Monster Renew grinder cartridge

Muffin Monster motor assembly

- 2.2 kW standard, 4.0 kW optional

- Optional explosion proof and immersible motors available

- 25:1 reducer, cycloidal design

Muffin Monster controller

- Ensures maximum grinding ability with minimum stoppage

- Designed and programmed for specified motor

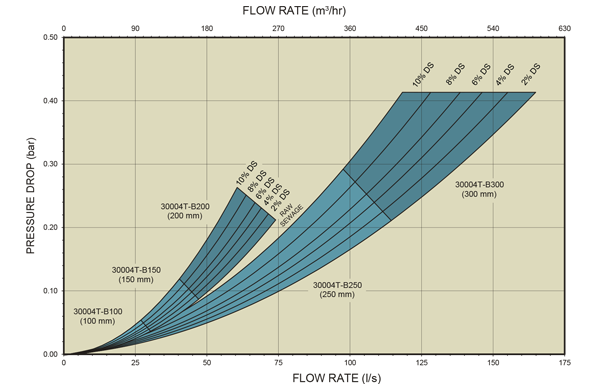

Performance curves

Muffin Monster grinder cutters

| Tooth count |

Thickness |

Material |

| 11-tooth |

8 mm |

Hardened alloy steel |

| 13-tooth |

5.5 mm |

Hardened alloy steel |

| 17-tooth Wipes Ready® |

11 mm |

Hardened alloy steel |

Muffin Monster grinder materials

| Part |

Material |

| Housings |

Ductile Iron |

| Cutters |

Hardened alloy steel |

| Shafts |

Hardened alloy steel |

| Mechanical seals |

Tungsten carbide faces |

| Gaskets |

Viton |

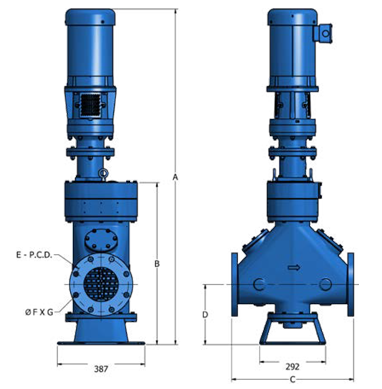

Dimensions (mm)

| |

|

|

|

Standart dimensions2, mm

|

Flange dimensions, mm |

|

|

Inline model

|

Flow rate1 , m3/h

|

Pipeline size, mm

|

Pressure drop, bar

|

A (IP55)

|

A (IP68)

|

В

|

С

|

D

|

E

|

F

|

G

|

Approximate net weight1- kg

|

| 30004T-B100 |

102 |

100 |

0.04 |

1425 |

1529 |

718 |

483 |

238 |

180 |

19 (M16) |

8 |

255 |

| 30004T-B150 |

159 |

150 |

0.08 |

1425 |

1529 |

718 |

534 |

264 |

240 |

23 (M20) |

8 |

254 |

| 30004T-B200 |

250 |

200 |

0.21 |

1425 |

1529 |

718 |

584 |

238 |

295 |

23 (M20) |

8 |

258 |

| 30004T-B250 |

386 |

250 |

0.20 |

1717 |

1821 |

1010 |

686 |

313 |

355 |

28 (M24) |

12 |

358 |

| 30004T-B300 |

556 |

300 |

0.40 |

1717 |

1821 |

1010 |

787 |

337 |

410 |

28 (M24) |

12 |

367 |

1 In-Line unit typically installed prior to suction side of pump. Consult factory for analysis of application.

2 Drive dimensions are a maximum based on a unit with a 4.0 kW drive.

30004T Muffin Monster grinder model coding

Product family

|

Solids reduction sewage grinder |

Q |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Grinder family |

30K Muffin Monster |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

| Grinder configuration |

New unit with motor (specified separately) |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

| |

Monster Renew cutter cartridge |

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

| |

Monster Renew cutter cartridge with spool |

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

| |

Monster Renew unit with unibody |

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

| |

Monster Renew unit with unibody & spool |

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

Cutter stack height and flange diameter

|

300 mm stack, 100 mm flange |

|

|

|

K |

1

|

|

|

|

|

|

|

|

|

|

| |

300 mm stack, 150 mm flange |

|

|

|

K |

2

|

|

|

|

|

|

|

|

|

|

| |

300 mm stack, 200 mm flange |

|

|

|

K |

3

|

|

|

|

|

|

|

|

|

|

| |

600 mm stack, 250 mm flange |

|

|

|

M |

4

|

|

|

|

|

|

|

|

|

|

| |

600 mm stack, 300 mm flange |

|

|

|

M |

5

|

|

|

|

|

|

|

|

|

|

| |

Monster Renew cutter cartridge 300 mm |

|

|

|

K |

Z |

|

|

|

|

|

|

|

|

|

| |

Monster Renew cutter cartridge 600 mm |

|

|

|

M |

Z |

|

|

|

|

|

|

|

|

|

Flange type

|

BS EN 1092, PN16 |

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

| |

Monster Renew cutter cartridge only |

|

|

|

|

|

Z |

|

|

|

|

|

|

|

|

| Cutter material |

Alloy steel |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

| Cutter |

7-tooth, 11 mm thick |

|

|

|

|

|

|

|

F |

3 |

|

|

|

|

|

| |

11-tooth, 8 mm thick |

|

|

|

|

|

|

|

H |

2 |

|

|

|

|

|

| |

17-tooth Wipes Ready®, 11 mm thick |

|

|

|

|

|

|

|

W |

4 |

|

|

|

|

|

| Body material & colour |

Cast iron blue |

|

|

|

|

|

|

|

|

|

S |

|

|

|

|

| Seals & gaskets material |

Severe duty seals & Viton gaskets |

|

|

|

|

|

|

|

|

|

|

V |

|

|

|

| Drum information |

Not applicable |

|

|

|

|

|

|

|

|

|

|

|

X |

X |

|

| Drive configuration |

Single drive |

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

| Example |

30004T-B200 with 17-tooth Wipes Ready cutters |

Q |

3 |

1 |

K |

3 |

D |

1 |

W |

4 |

S |

V |

X |

X |

S |

Muffin Monster motor assembly

| Power |

Voltage |

Protection type |

Motor model code |

| 2,2 kW TEFC |

400V, 3-phase, 50 Hz |

IP55 (standard) |

QD1435B2M |

| 2,2 kW TEFC |

400V, 3-phase, 50 Hz |

IP55 for ATEX (Ex d IIC T4) |

QD2435B2M |

| 2,2 kW Immersible |

400V, 3-phase, 50 Hz |

IP68 for ATEX (Ex de IIB T4) |

QD3435B1M |

| 4,0 kW TEFC |

400V, 3-phase, 50 Hz |

IP55 (standard) |

QE1435B2M |

| 4,0 kW TEFC |

400V, 3-phase, 50 Hz |

IP55 for ATEX (Ex d IIC T4) |

QE2435B2M |

| 4,0 kW Immersible |

400V, 3-phase, 50 Hz |

IP68 for ATEX (Ex de IIB T4) |

QE3435B2M |

Muffin Monster controller

| Grinder motor type |

Model code for IP65 control panel enclosure |

|

| |

Powder coated mild steel material |

Stainless steel material |

| 2.2 kW IP55 |

QL1P45XXX |

QL1S45XXX |

| 2.2 kW IP68 |

QL2P45XXX |

QL2S45XXX |

| 4.0 kW IP55 |

QM1P45XXX |

QM1S45XXX |

| 4.0 kW IP68 |

QM2P45XXX |

QM2S45XXX |