Sulzer turbocompressor HST 20

Single-stage centrifugal compressor for absolutely oil-free supply of air. The turbocompressor featuring variable speed control for continuously variable power optimization according to the changes in inlet conditions and differential pressure.

Construction

- Frequency converter

- Totally oil-free magnetic bearings

- Blow-off valve with silencer

- Local control

- All safety control required for monitoring

- Sound isolation enclosure

- All mounted on a common base plate

- Integrated high speed electric motor

- Accessories for inlet/outlet (as options)

High speed electric motor

Air cooled variable speed high frequency electric motor. The impeller and the motor cooling fan are mounted directly to the motor shaft. Vertically mounted motor with magnetic bearings and variable rotation speed.

Frequency converter

In-built frequency converter for variable motor speed control and optimal efficiency at all operation points. Start-up with soft start function. Includes RFI-filter that attenuates the radio frequency interference.

Impeller

Impeller shaped from a solid piece of high-strength aluminium alloy on a numerical machining center in CAM technology. Impeller design with 3 dimensional shaped blades, individually optimized to the design range of the compressor.

Magnetic bearings

Two radial bearings with 8 pole magnets each and two axial magnetic bearing with 2 pole magnets each and continuous rotor position measurement controlled by active magnetic bearing controller. Including RFI-filter.

Features:

- No mechanical contact between surfaces

- No mechanical friction

- No wearing

- No oil lubrication

- Vibration free operation

- Continuous rotor balance monitoring and unbalance compensation

Directives

- Machinery Directive (MD), 2006/42/EC, 2009/127/EC.

- Low Voltage Directive (LVD), 2006/95/EC.

- Electromagnetic Compatibility (EMCD), 2004/108/EC.

- Available as CE or UL certified.

The product is designed and manufactured to be connected to industrial network in accordance with EN 61800-3 standard. (EMC product standard for adjustable speed electrical power drive system).

Test run

Performance test and acceptance according to ISO 5389 will be performed on Sulzer test stand and attested. The design values of the performance are guaranteed within a manufacturing tolerance of ± 2%. The measurement uncertainty is evaluated according to ISO 5389.

Cooling air quality

|

Permitted chemical

vapours according

to IEC 60721-3-3 class 3C3

|

Ave. / Max

[mg/m³]

|

| Sulphur dioxide (SO2) |

5,0 / 10 |

| Hydrogen sulphide (H2S) |

3,0 / 10 |

| Chlorine (Cl) |

0,3 / 1,0 |

| Hydrogen chlorine (HCl) |

1,0 / 5,0 |

| Hydrogen fluoride (HF) |

0,1 / 2,0 |

| Ammonia (NH3) |

10 / 35 |

| Ozone (O3) |

0,1 / 0,3 |

| Nitrogen oxides (NOx) |

3,0 / 9,0 |

Compressor control

Connections

Analog and Digital I/O as standard

Ethernet

Profibus, Modbus or DeviceNet (as an option)

Local control and monitoring

Color touch screen

Widely customizable monitoring content to suitindividual requirements

Visualized efficiency monitoring for optimal energy usage

Extensive diagnostics, trends and log files

Remote control and monitoring

Available via internet, local network or modem (as an option)

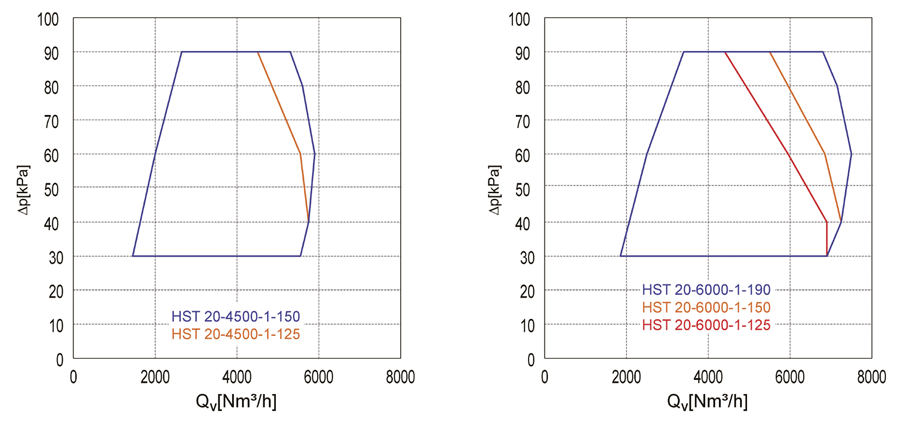

Compressor data

|

HST 20

|

-4500-1-125

|

-4500-1-150

|

-6000-1-125

|

-6000-1-150

|

-6000-1-190

|

|

Air flow range [Nm3/h]

|

2000-5500

|

2000-5800

|

2000-6500

|

2000-6750

|

2000-7000

|

|

Pressure rise [kPa]

|

30-90

|

30-90

|

30-90

|

30-90

|

30-90

|

|

Max noise level [dB]

|

70

|

70

|

70

|

70

|

70

|

|

Input power [kW]

|

125

|

150

|

125

|

150

|

190

|

|

Max. current (400V) [A]

|

198

|

238

|

198

|

238

|

301

|

|

Max. current (500V) [A]

|

159

|

190

|

159

|

190

|

241

|

|

Max. current (690V) [A]

|

115

|

138

|

115

|

138

|

175

|

|

Power supply [V]

|

380-690

|

380-690

|

380-690

|

380-690

|

380-690

|

|

Input power frequency [Hz]

|

50/60

|

50/60

|

50/60

|

50/60

|

50/60

|

|

Protection class

|

IP 33D

|

IP 33D

|

IP 33D

|

IP 33D

|

IP 33D

|

|

Thermal protection

|

Pt100

|

Pt100

|

Pt100

|

Pt100

|

Pt100

|