AHLSTAR End Suction Single Stage Close Coupled Centrifugal Pump

AHLSTAR End Suction Single Stage Close Coupled Centrifugal Pump

Applications

AHLSTAR pumps have been designed to meet the most demanding hydraulic coverage requirements and for all types of liquid, making it the ideal range for challenging pumping operations.

The pumps are also suited to the pumping of liquids with a high gas content of up to 40% of free gases or up to 70% of bound gases.

Areas of application:

- Oil and gas

- Hydrocarbon processing

- Power generation

- Pulp and paper

- General industry

- Water and wastewater

Features and Benefits

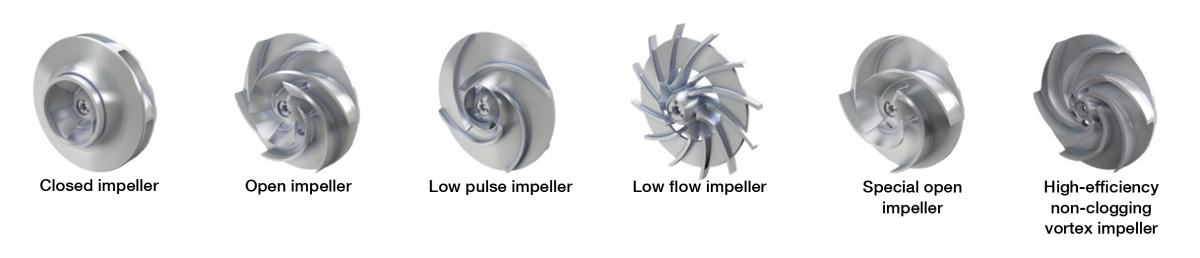

Versatile selection of reliable, high efficiency Sulzer EnerSave™ impellers

- Reduce life-cycle costs, especially energy consumption, operation time and downtime costs

Innovative and reliable integrated degassing and self-priming units

- For a variety of applications with difficult liquids

- Designed to help the centrifugal pump start quickly when the liquid level is below the pump in self-priming applications

Patented, strong, reliable Rotokey impeller mounting

- Enables an easy and quick dismantling and assembly

- Helps to minimize maintenance costs

Patented externally adjusted side plate

- Allows easy and quick impeller clearance setting to maintain continuous high efficiency and minimize life-cycle costs

Patented balancing holes

- Secure good liquid circulation behind the impeller and in the seal chamber

- Guarantee optimal conditions for shaft seal by reducing unexpected shutdowns and minimizing operation and maintenance costs

Proven Sulzer WaterLess™ shaft seal

- Dynamic seal, single and double mechanical seals, gland packing

- Cost savings with fast and easy installation

- No measurements needed

Standard IEC dimensioned flange or flange/feet electric motor with heavy-duty bearing unit arrangement

- Shrink fitted sturdy shaft which is equally dimensioned with the shaft of AHLSTAR long coupled pump

- Possible to use same wet end and sealing unit components which helps minimizing spare part inventory costs

Heavy-duty shaft

- Minimizes deflection at stuffing box to less than 0.05 mm / 0.002 in

- Helps to extend the shat seal lifetime and reduces unexpected shutdowns and maintenance costs

Jackscrews

- Enable simple disassembly while minimizing maintenance costs

Operating data

| Liquid |

Temperature up to 130°C / 266°F

|

Pressure up to 16/25 bar / 230/360 psi

|

Gas content up to 70% |

Liquid position below or above the pump |

Corrosion pH from 0 to 14 |

| Clean and slightly contaminated liquids |

+ |

+ |

+ |

+ |

+ |

| Viscous liquids |

+ |

+ |

+ |

+ |

+ |

| Fibrous slurries |

+ |

+ |

+ |

+ |

+ |

| Non-fibrous slurries |

+ |

+ |

+ |

+ |

+ |

| Large solids containing liquids |

+ |

+ |

+ |

+ |

+ |

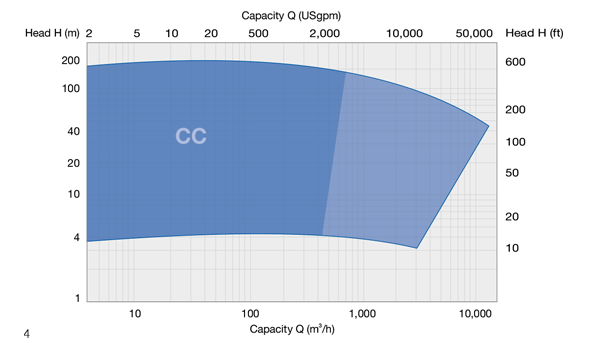

| Capacities |

600 m3/h / 2,900 USgpm |

| Heads |

160 m / 525 ft |

| Temperatures |

130°C / 266°F |

| Frequencies |

50 or 60 Hz |

| Pressures |

16/25 bar, 230/360 psi depending on material and size |

Performance ranges

Impeller options

Materials

Materials

|

Standard material options

|

|

|

|

|

| Duplex SS |

ASTM

|

A890

|

Grade 3A |

41 |

| Duplex SS |

ASTM |

A890 |

Grade 1B |

4L |

| Duplex SS |

ASTM |

A890 |

Grade 5A |

4T |

| Duplex SS |

|

|

Sulzer 2304 |

EJ |

| Austenitic |

ASTM |

A743 |

Grade CF-8 |

4C |

| Austenitic |

Avesta |

A743 |

654 SMO* |

4U |

|

Martensitic

|

ASTM |

A747 |

Grade CB7Cu-2 |

4E |

|

Cast Iron

|

ASTM |

A48 |

CL 35 B |

53 |

| Carbon Steel |

ASTM |

A216 |

WCB |

46 |

Other materials on request.

* Trademark owned by Outokumpu Stainless