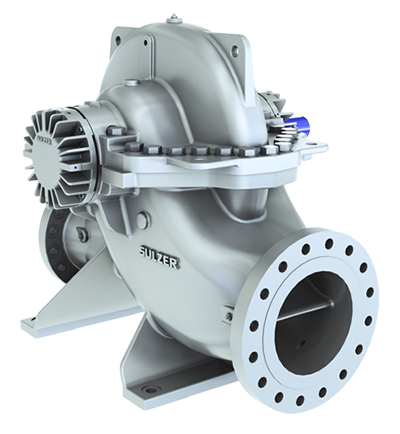

SMD Axially Split Casing, Double Suction Pump

SMD Axially Split Casing, Double Suction Pump

Applications

SMD single stage, double suction, axial split casing pumps are designed to meet the needs of the water market for a wide range of raw, clean, sea and brackish water applications:

- Water abstraction

- Water transport

- Desalination

- Water treatment

- Water supply and distribution

- Irrigation, drainage and flood control

- District cooling/heating

Suitable for drinking water applications. ACS, NSF 61 and WRAS certificates available upon request. To meet the demands of the individual applications, the SMD benefits from a best-in-class hydraulic design that is combined with two specific mechanical envelopes:

- Standard SMD, focused on municipal water treatment, supply and distribution where typically a higher level of standardization is required, allowing the most cost effective solutions and shortest lead times.

- Configured SMD combines standardization and modularization to offer a number of configurable options to meet the most common requirements of the water abstraction, transport and desalination industries.

Features and Benefits, Standard SMD

Double suction impeller

- With inherent hydraulic balance of axial thrust

- Exceptional efficiency over a wide range of flows

- Excellent Net Positive Suction Head Required (NPSHR) also in flow run out conditions

Double volute casing

- Radial load balancing

- Innovative cut-water design for minimum radial load pulses and reduced vibrations

- Self-draining

- Compact dimensions for reduced bearing span and improved shaft stiffness

360° bearing bracket ours

- 360° fixation for enhanced stiffness

- Greased for life, deep groove single ball bearings at both drive and non-drive ends

Easy maintenance

- Full dry-shaft design prevents rusting

- Single, balanced mechanical seal as standard shaft sealing

- Dowel pins for alignment of the casing halves

- Precision register fits, adjustment of rotor assembly in the casing is not needed

- Bearings, bearing nuts, bearing isolators mechanical seal, shaft seal sleeves are replaceable without removing the upper casing

Features and Benefits, Configured SMD

Heavy duty bearing design

- For higher power requirements, typically in large water transport applications

- With angular contact, double ball bearing at drive end and single radial ball bearing at the non-drive end

- Grease or oil lubricated bearings available

Shaft sealing

- Gland packing available as an option

- Other mechanical seal configurations available upon request

SMD Optional Features

Vertical arrangement

- With grease lubricated thrust bearing at the drive end and product lubricated proven design bearing at the non-drive end

- Interchangeable casing with the horizontal arrangement

Bearings

- Cooling fan in thrust bearing for heavy duty applications such as high speed, high ambient temperature, provides effective cooling without need of cooling water

- Connection for temperature and vibration monitoring instruments

Impeller wear ring

- Shrink fit and axially secured

- Offers additional impeller protection

- Reduced maintenance cost in heavy duty applications

Seal plan options

Plan 11 as standard, with seal plans 31 and 32, with cyclon separator or with external flushing source

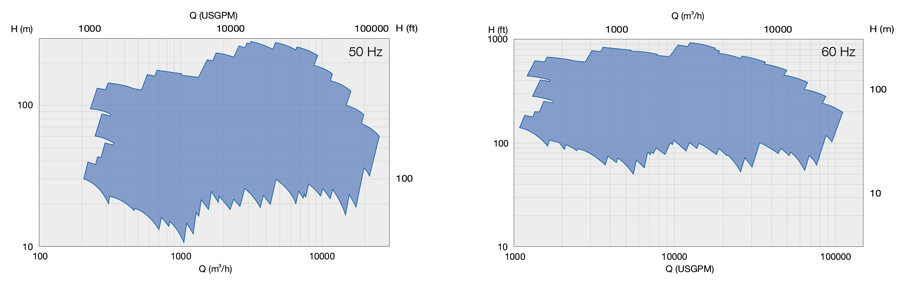

Operating data

| |

50 Hz

|

60 Hz

|

| Pump sizes |

150 to 1,000 mm |

6 to 40 in |

| Capacities |

200 to 25,000 m3/h |

1,100 to 110,000 USgpm |

| Heads |

up to 260 m |

up to 850 ft |

| Pressures |

up to 34 bar |

up to 490 psi |

| Temperatures |

up to 140°C |

up to 280°F |

Performance ranges

Materials

|

Pump part

|

|

|

|

|

|

| Casing |

Ductile iron |

Ductile iron |

Carbon steel |

Duplex |

Super Duplex |

| Impeller |

Duplex |

Duplex |

Carbon steel |

Duplex |

Super Duplex |

|

Shaft

|

Chromium steel |

Chromium steel |

Chromium steel |

Duplex |

Super Duplex |

|

Seal housing

|

Ductile iron |

Ductile iron |

Carbon steel |

Duplex |

Super Duplex |

| Stationary ring |

Aluminum bronze |

Duplex |

Alluminum bronze |

Duplex |

Super Duplex |

| Impeller ring* |

Duplex

|

Duplex + Stellite 6

|

Carbon steel

|

Super Duplex + Stellite 6

|

Duplex + Stellite 6

|

* Optional