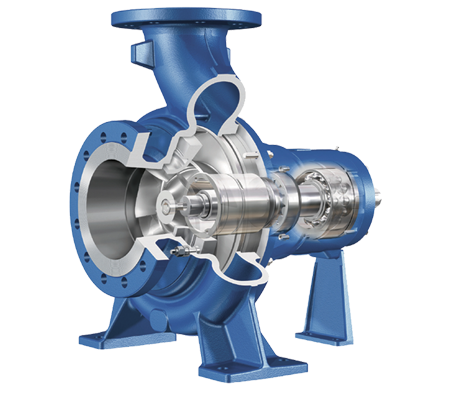

BE End Suction Single-Stage Centrifugal Pump

BE End Suction Single-Stage Centrifugal Pump

Applications

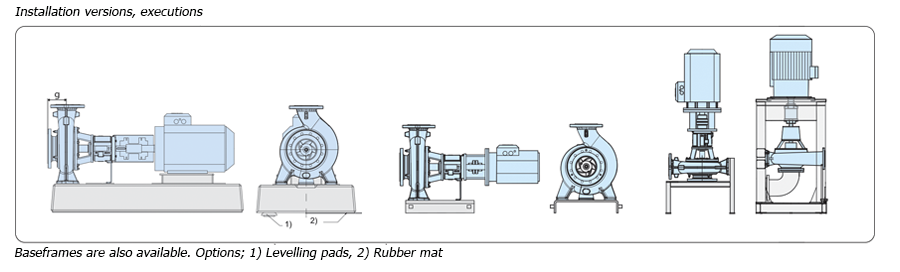

Sulzer process pump BE is specially designed for pulp and paper applications, e.g. – paper, tissue and board machines, chemical-, mechanical- and recycled fibre lines, chemical recovery as well as effluent treatment plant etc. They are also very well suited for general industry and wastewater applications.

Design

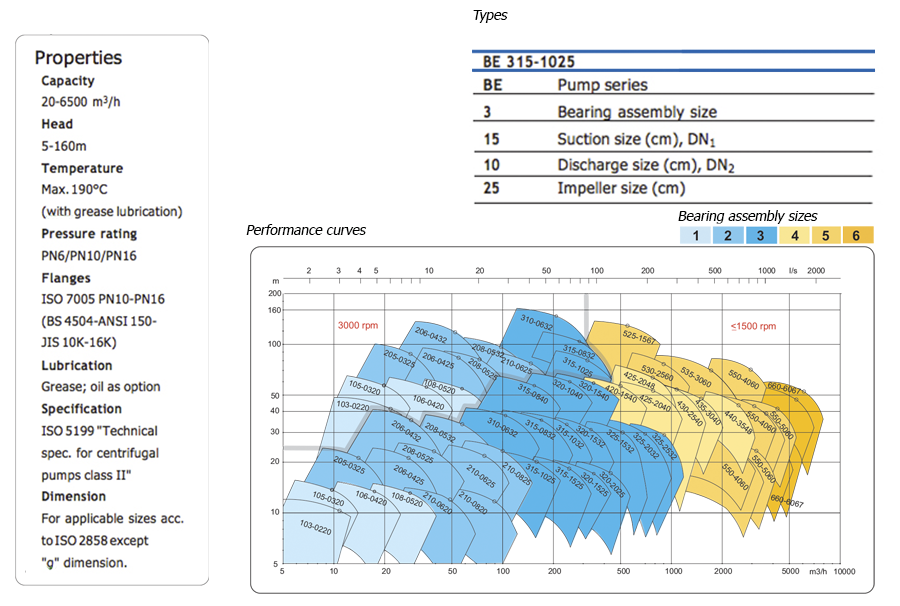

The BE series includes 39 pump sizes and is built on a modular design, which offer high interchangeability, simplified service and a low number of spare parts. This means that low maintenance costs can be obtained.

Pump casing

Rugged BE pump construction creates longterm wear resistance. The generous wall thickness and the casing’s smooth, pocket-free interior protect against erosion and corrosion.

Impeller

The impellers can handle almost any suspensions and a huge range of slurries. The pumps are available with semi-open impellers. A new hydraulic design for semi-open impellers features large free passages. The sturdy construction ensures high wear resistance, resists corrosion and reduces sensitivity to foreign objects. When the BE pump is used as medium sized fan or dilution pumps, ESDF impellers, special low pulsations impellers are used. For some sizes vortex impellers can also be selected. These impellers have an improved vane design offering clogless and trouble-free operation. A hexagonal shaft secures the impeller fixing, giving stable operation conditions and long MTBF (Mean Time Between Failure).

Wear disc

The wear disc is replaceable and can be easily adjusted from the pump casing’s front. This makes it easy to maintain high efficiency over the entire lifetime of the pump and ensures shorter MTTR (Mean Time To Repair). The sealing of the pump casing has also been improved.

Shaft

The shafts are sturdy, with a deflection of less than 0.05 mm at the seal areas under normal running conditions. All shafts are protected by a replaceable sleeve in stainless steel or higher quality alloys.

Shaft seals

The alternatives include single and double mechanical seals, gland packing and dynamic seals, with a variety of material to suit every application.

Bearing assembly

The bearing assembly of a BE pump features a sturdy design that ensures long MTBF, long pump lifetime and low maintenance costs. Six different bearing sizes cover all pump in the series, and all bearings have angular contact ball bearings at the driven end.

Standard bearing assemblies are lubricated with grease, though oil is also an option. On oil-lubricated bearing assemblies, two inspection eyes are standard. This makes it easy to inspect the bearing assembly from both sides.

Your benefits

- Large energy savings. Improved hydraulic design creates greater efficiency in each individual pump minimising the average power consumption.

- Total reliability. Robust design, secure impeller fastening and sturdy bearing assembly ensure long pump lifetime. Better performance coverage for better runnability gives exceptional MTBF.

- Simplified service. Smart pump design with maintenance-reducing features. Modular construction with few parts to service and store.

Materials

|

Code

|

03**)

|

05**)

|

24**)

|

08

|

09

|

21

|

23

|

25

|

26

|

27

|

32

|

|

Pump

casing

|

Cast

iron

|

Cast

iron

|

SS

2324*)

|

Nodular

iron

|

Nodular

iron

|

SS

2399

|

SS

2324*)

|

SS

1.4517*)

|

SS

1.4408

|

SS

1.4527

|

Nickel***)

S6371

|

|

Wear

disc

|

Cast

iron

|

SS

2324*)

|

SS

2324*)

|

Cast

iron

|

SS

2324*)

|

SS

2399

|

SS

2399

|

SS

1.4517*)

|

SS

1.4408

|

SS

1.4527

|

Nickel***)

S6371

|

|

Impeller

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2399

|

SS

2399

|

SS

1.4517*)

|

SS

1.4408

|

SS

1.4527

|

Nickel***)

S6371

|

|

Shaft

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS 2324*)

|

|

Shaft

sleeve

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

2324*)

|

SS

1.4539

|

SS

2324*)

|

SS

1.4539

|

Nickel***)

S6371

|

*) Duplex stainless steel. **) Standard material combinations. ***) Nickel alloy.