Z22 Double-Suction Axially-Split Single-Stage Centrifugal Pump

Z22 Double-Suction Axially-Split Single-Stage Centrifugal Pump

Applications

Sulzer split casing pump, series Z22, our workhorse for many demanding operations. They are trusted for pulp and paper production as head box pumps and dilution pumps. In water and sewage works, district heating systems, power plants and other critical applications.

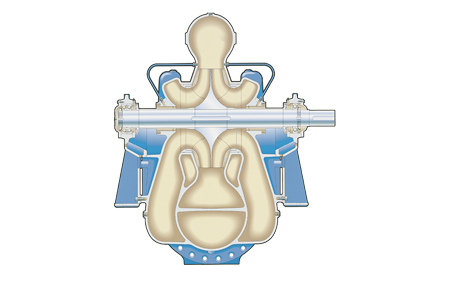

Design

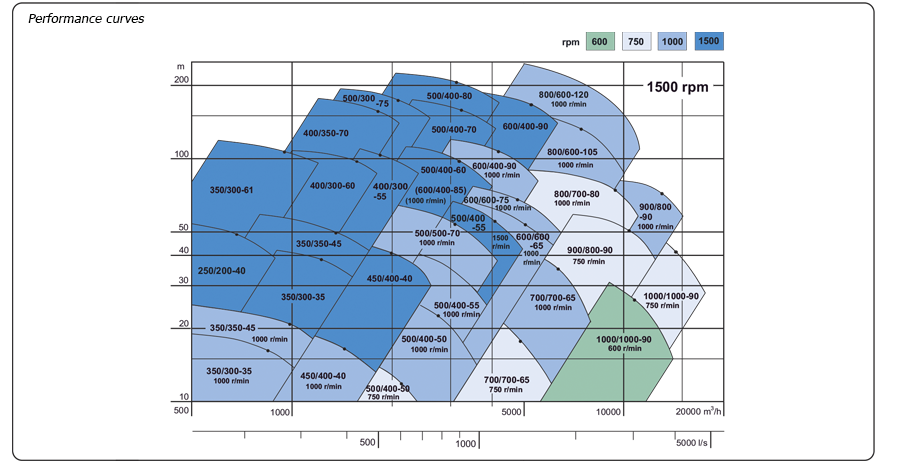

The Z22 series comprises of 24 sizes with different impeller design available. This flexibility ensures that energy consumption is minimised throughout a pumps’ complete operating range. Many of these pumps have a peak efficiency of over 90%. Each pump is tested to ISO 9906, Grade 2, or other agreed standard.

Pump casing

Pumps generating high heads are designed to reduce radial forces, ensuring minimal shaft deflection and low bearing loads.

The casing is axially split, which permits removal of the complete rotor without moving either the piping or the motor.

Replaceable wear rings between the suction and discharge side enable high efficiency throughout the whole lifetime of the pump.

Impeller

The closed impellers are designed for optimum flow conditions. Each impeller is dynamically balanced according to ISO 1940, Grade 6.3 (For fan pump Grade 2.5).

Double suction low pulsation impellers are available designed to meet stringent performance requirements for head box pumps. These impellers gives practically zero hydraulic axial forces and have low NPSH requirements which gives reduced installation costs.

For each pump size there are normally two or more impeller variants available to best suit various applications.

Shaft and shaft sleeves

Sturdy shaft/bearing construction ensures smooth running with very low vibrations.

The shaft deflection at the seal positions is less than 0.05 mm. At its entire length the shaft is protected by shaft sleeves, which are O-ring sealed.

Shaft seals

All sizes can be supplied with mechanical seals and most sizes with gland packing.

Bearings

Grease lubricated bearings designed for a calculated bearing life of at least 80 000 hours, which is equivalent to 10 years continuous service. Only maintenance of bearings and shaft seals are necessary.

Deflectors and V-ring seals protect the bearings against moisture and dirt ingress both when running or at standstill.

The bearing brackets are drilled as standard for SPM nipples and can also be fitted with temperature sensors.

The rigid axial thrust bearing can take high external axial loads, and the pumps can therefore be vertically mounted.

Your benefits

- Optimal reliability. Sturdy design ensures smooth and trouble-free operation.

- High efficiency.The design guarantee high effciencies and large energy savings year in and year out.

- Low installation costs. Double suction impellers with lower NPSH requirements give minimal installation costs.

- Maximum flexibility. Wide range with many installation op- tions to meet specific applications needs.

- Simplicity of service. Easy dismantling thanks to the split casing design.

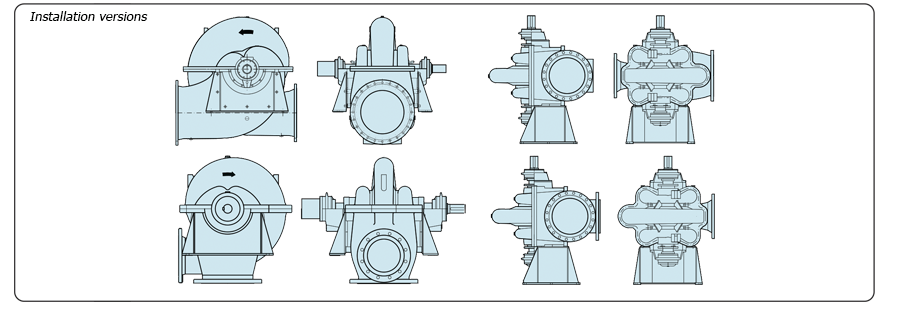

Installation versions

All pumps can be installed horizontally or vertically and some can be supplied with right-angle connections.

Flexible steel support design makes it easily to adopt customers special requirements, mostly incline suction discharge configuration.

For vertical installations the motor can be mounted on a tripod and driven via a cardan shaft to the stool-mounted pump. The pump can also be mounted on a stool and driven via a cardan shaft.

Type designations

| Z22 800/700-80 |

|

| Z22 |

Pump series |

| 800 |

Inlet dia. (mm) |

| 700 |

Outlet dia. (mm) |

| -80 |

Impeller dia. (cm) |

Materials

|

Code

|

01

|

02

|

05

|

06

|

07

|

24

|

41

|

|

Pump casing

|

Grey cast iron

A48 CL 30 B

|

Grey cast iron

A48 CL 30 B

|

Grey cast iron

A48 CL 30 B

|

Ductile iron

A395 60-40-18

|

Ductile iron

A395 60-40-18

|

Duplex steel

A890 3A**)

|

Cu alloy

EN CC492K

|

|

Wear rings

|

Grey cast iron

A48 CL 30 B

|

CuSnPb alloy

CuSn5PbZn5

(CC491K)-GS

|

Grey cast iron

A48 CL 30 B

|

Grey cast iron

A48 CL 30 B

|

CuSnPb alloy

CuSn5PbZn5

(CC491K)-GS

|

Duplex steel

A890 3A**)

|

CuSnPb alloy

CuSn5PbZn5

(CC491K)-GS

|

|

Impeller

|

Grey cast iron

A48 CL 30 B

|

Cu alloy

EN CC492K

|

Duplex steel

A890 3A**)

|

Grey cast iron

A48 CL 30 B

|

Cu alloy

EN CC492K

|

Duplex steel

A890 3A**)

|

Cu alloy

EN CC492K

|

|

Shaft

|

Carbon steel

C45E+QT

|

Carbon steel

C45E+QT

|

Duplex steel

EN 1.4460*)

|

Carbon steel

C45E+QT

|

Carbon steel

C45E+QT

|

Duplex steel

EN 1.4460*)

|

Duplex steel

EN 1.4460*)

|

|

Shaft sleeve

|

CuSnPb alloy

CuSn5PbZn5

(CC491K)-GS

|

CuSnPb alloy

CuSn5PbZn5

(CC491K)-GS

|

Duplex steel

EN 1.4462*)

|

CuSnPb alloy

CuSn5PbZn5

(CC491K)-GS

|

CuSnPb alloy

CuSn5PbZn5

(CC491K)-GS

|

Duplex steel

EN 1.4462*)

|

CuSnPb alloy

CuSn5PbZn5

(CC491K)-GS

|