VMS Vertical Multi-Stage Pumps

VMS Vertical Multi-Stage Pumps

Applications

Vertical, single or multi-stage centrifugal pump series, for the stand-alone pumping of clean domestic, commercial and process water, or in pressure boosting systems for building technology and industry.

A VMS pump is designed for reliable operation in a wide range of applications e.g.:

- Domestic and municipal drinking water supply

- Food, chemical, and process industries

- Transportation in cool or hot water applications

- Fire-extinguishing systems

- Cleaning and washing facilities

Allowable temperature range of the medium is -20 - +140 °C (VMS 125 @ PN16 max. +80 °C, VMS 125 @ PN25 max. +120 °C, VMS H 6: -15 - +80 °C)

Drinking Water Certificates

Constructed from 1.4301 or 1.4401 stainless steel, and with WRAS, ACS and NSF certification, makes the VMS suitable for the pumping of drinking water.

Motor

T.E.F.C. (totally enclosed fan cooled) squirrel cage, three-phase and single-phase, 50 Hz, 2-pole and 4-pole AC induction motors.

Motor efficiency (≥ 0.75 kW): IE2 or IE3

Insulation class: F

Protection type: IP 55

Temperature rise class: B

Duty class: S1 (maximum 20 starts per hour)

Noise levels: conform to IEC 60034-9

Optional as explosion proof class Ex e II T3 and Ex e II T4.

Bearings

Medium-lubricated stage bearing, tungsten carbide against ceramic.

Temperature monitoring

> 2.2 kW standard with 3 x PTC.

Connections

Options of external thread with built-in non-return valve, counter flange, victaulic, triclamp, or round flange, in stainless steel 1.4301 or 1.4401, to pressure class PN 10, 25 or 40.

Shaft sealing

Fixed, easy access, or cartridge configurations to suit specific pump duty and application.

Operating data

| Seal part |

Materials and options

|

| Construction material |

CrNiMo steel (1.4571) |

| Spring material |

CrNiMo steel (1.4571) |

| Face material |

Carbon graphite antimony impregnated

Carbon graphite resin impregnated

SiC, silicon carbide, sintered

Tungsten carbide, NiCrMo-binder |

| Elastomer |

Ethylene propylene rubber (EPDM)

Fluorcarbon rubber (FKM)

Hydrogenated Nitrile-rubber (HNBR) |

Features

Modular construction offers a wide number of variations in materials, seals, connectors, motors, etc.

- Easily accessible for servicing, often without the need to disassemble the pump or motor, or need for special tools.

- Wide variety of pump bases, connections and seals.

- Stainless steel base and hydraulic parts ensure the conservation of water quality during transport.

- Efficient fluid flow-through specially designed pump base and head piece for high energy efficiency and long life.

- Provision of plugs for draining, venting, and measuring of suction and discharge pressure.

- In-line suction and discharge connections for ease of installation.

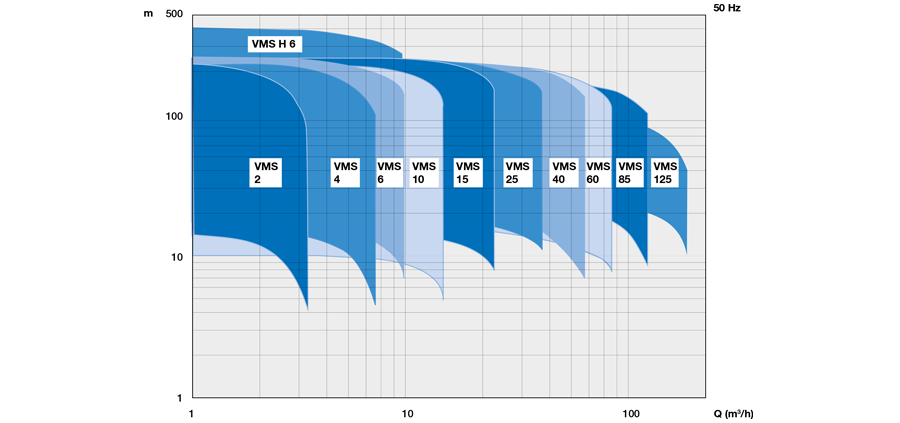

Working range

| Description |

Range

|

| Ambient temperature [°C] |

-20 … +40 |

| Minimum inlet pressure |

NPSHreq. + 1 m |

| Viscosity [cSt] |

1-100 |

| Density [kg/m3] |

1000 – 2500 |

| Cooling |

Forced motor cooling |

| Minimum frequency [Hz] |

30 |

| Maximum frequency [Hz] |

60 |

| Allowable size of solids pumped |

5 μm to 1 mm |

| Head [H] |

3 - 254 mwc (VMS H 6 = 400 m) |

| Flow range [Q] |

0.2 - 160 m3/h |

Technical data (50 Hz)

| |

VMS 2

|

VMS 4

|

VMS 6

|

VMS H 6 |

VMS 10 2P

|

VMS 10 4P

|

VMS 15 2P

|

VMS 15 4P

|

VMS 25 2P

|

| Capacity range [m3/h] |

0.2 - 3.3 |

0.4 - 6.5 |

0.6 - 9 |

0.6 - 8.6 |

1.0 - 13.2 |

0.5 - 6.6 |

1.8 - 22.5 |

0.98 - 11.3 |

2.8 - 35 |

| Nominal capacity at Qopt. [m3/h] |

1.9 |

4 |

6.3 |

6.5 |

10 |

5 |

18 |

9.8 |

28 |

| Norm pressure |

PN 10 - 25 - 40 |

| Maximum pump pressure [m] |

229 |

234 |

256 |

402 |

239 |

58 |

248 |

59 |

246 |

| Maximum pressure at Qopt. [m] |

187 |

193 |

200 |

325 |

179 |

43 |

193 |

44 |

185 |

| NPSH at Qopt. [m] |

2.2 |

1.2 |

1.2 |

2.0 |

1.2 |

0.9 |

1.2 |

0.6 |

3.0 |

| Maximum efficiency |

54% |

62% |

68% |

60% |

68% |

68% |

71% |

71% |

77% |

| |

VMS 25 4P

|

VMS 40 2P

|

VMS 40 4P

|

VMS 60 2P

|

VMS 60 4P

|

VMS 85

|

VMS 85 4P

|

VMS 125 |

| Capacity range [m3/h] |

1.4 - 17.5 |

4 - 54 |

2 - 27 |

6 - 76 |

3 - 38 |

8.5 - 112.8 |

4.3 - 54 |

13.1 - 162 |

| Nominal capacity at Qopt. [m3/h] |

14 |

40 |

19 |

54 |

26.5 |

85.7 |

40 |

125.0 |

| Norm pressure |

PN 10 - 25 - 40 |

| Maximum pump pressure [m] |

59 |

239 |

59 |

251 |

71 |

176 |

42 |

128 |

| Maximum pressure at Qopt. [m] |

45 |

194 |

50 |

193 |

55 |

132 |

33 |

88 |

| NPSH at Qopt. [m] |

0.8 |

2.5 |

0.6 |

2.7 |

0.7 |

2.2 |

0.6 |

5.0 |

| Maximum efficiency |

77% |

76% |

76% |

78% |

78% |

79% |

79% |

80% |

Performance ranges