Sulzer submersible dranaige pump J 604

Sulzer submersible dranaige pump J 604

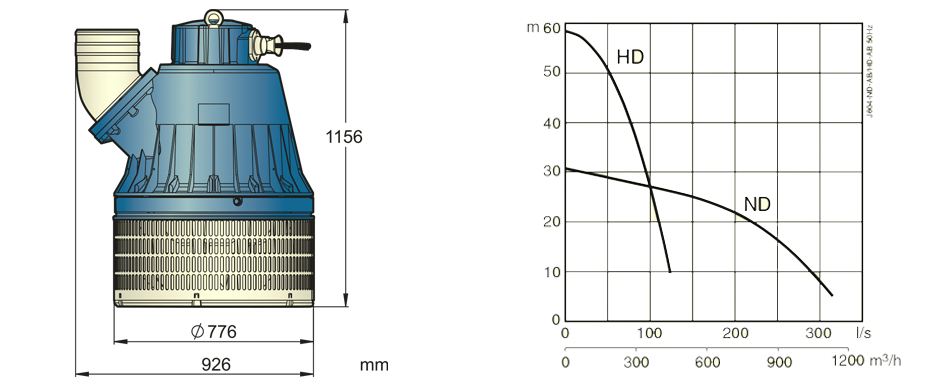

The low weight and compact design of the submersible drainage pump J 604 ensure convenient transport, handling, and installation. The pump is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: head max 58 meters, flow max 330 l/s. 60 Hz: head max 70 meters (230 feet), flow max 340 l/s (5397 gpm).

Specification

Electric submersible pump. Maximum submergence: 20 m. Protection class IP 68.

Max temperature of pumped medium at max power input and continuous duty 40 ºC.

Max medium density 1100 kg/m3. pH of the pumped medium 5-8. Strainer hole: 12 x 60 mm.

Max number of starts 30/hour.

Electric motor

3-phase squirrel-cage induction motor, 50 Hz:

Service factor 1.1. Class F insulation.

Motor rating P2: 56.0 kW.

Speed: 1450 rpm.

| Voltage, V |

230 |

400 |

500-550 |

690 |

1000 |

| Nominal current, A |

184 |

106 |

84 |

61 |

42 |

Starting method and motor protection

D.O.L. start with built-in terminal block.

Star-Delta start with built-in terminal block.

When used with VFD, pump must be equipped with terminal block.

Power cable

20 m type H07RN8-F (standard cable):

2-4x16 sq.mm.+H07RN8-F 7x1.5 sq.mm. (400-550 V star-delta start)

2-4x10 sq.mm.+H07RN8-F 7x1.5 sq.mm. (690 V star-delta start)

4x25 sq.mm.+H07RN8-F 7x1.5 sq.mm. (690 V DOL-start)

20 m type H07RN8-F (standard cable):

2-4x35 sq.mm.+H07RN8-F 7x1.5 sq.mm. (230 V star-delta start)

4x35 sq.mm.+H07RN8-F 7x1.5 sq.mm. (400-550 V DOL-start)

20 m type NSSHÖU.../3E (heavy duty cable):

3x10+3x10/3E+3x2.5 (3 control cables included) (1000 V DOL-start)

3x16+3x16/3E+3x2.5 (3 control cables included) (690 V DOL-start)

3x25+3x16/3E+3x2.5 (3 control cables included) (400-550 V DOL-start)

Motor protection

Built-in thermal switches in the stator winding (140ºC, ±5).

DI leakage sensor in the junction box, DI leakage sensor in the oil chamber, thermal sensors at upper (120ºC) and lower (90ºC) bearing connected to a separate starter and control unit.

Shaft seal

Double mechanical seal in oil bath.

Primary seal: Silicon carbide on silicon carbide.

Secondary seal: Carbon on stainless steel.

Bearings

Upper bearing: Single-row deep groove ball bearing.

Lower bearing: Double angular contact ball bearing.

Discharge connections

6" (standard HD), 8", 10" (standard ND) hose connections.

6", 8" G/B.S.P. threaded connections

Weight

525 kg (without cable)

Options and accessories

Zinc anodes. Surface protection coating.

Wear plate in polyurethane. Series connection (HD).

Starter and control units. Automatic level control unit.

Floatation system. Repair kit.

Discharge connection accessories and hose.

Materials

| Description |

Material |

EN |

ASTM |

| Castings |

Aluminium |

EN 1706:AC-43100 |

ASTM AlSi10mg |

| Casing / Fasteners |

Stainless steel |

10088:X5CrNi18-10 (1.4301) |

AISI 304 |

| Shaft |

Stainless steel |

10088:X20Cr13 (1.4021) |

AISI 420 |

| Impeller |

White cast iron |

EN-GJN-HV600(XCr23) |

ASTM A 532: Alloy III A |

| Wear parts / O-rings |

Nitrile rubber |

|

|