Sulzer submersible sludge pump XJS 110

Sulzer submersible sludge pump XJS 110

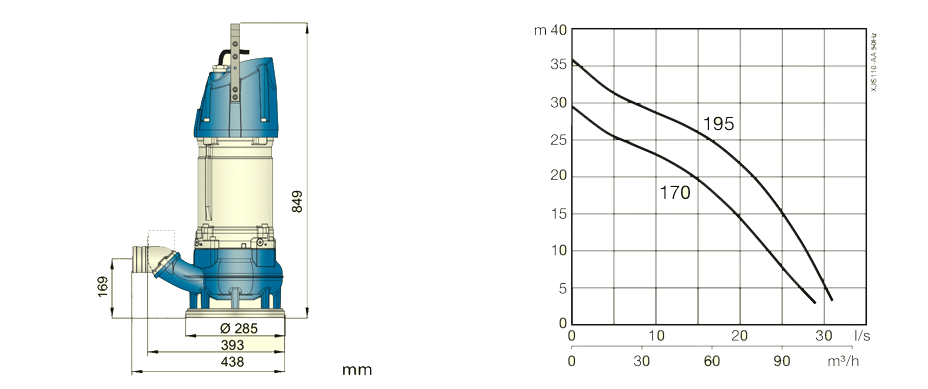

The submersible sludge pump XJS 110 is ideal for pumping sludge and water mixed with solids. Pumps with built in AquaTronic unit will always have correct direction of impeller rotation, ensuring peak performance and reduced wear. 50 Hz: head max 36 meters, flow max 31 l/s. 60 Hz: head max 40 meters (131 feet), flow max 30 l/s (476 gpm).

Specification

Electric submersible pump.

Maximum submergence: 20 m. Protection class IP 68.

Max temperature of pumped medium at max power input and continuous duty 40 ºC.

Max medium density 1100 kg/m3. pH of the pumped medium 5-8. Free passage: 48 x 60 mm.

Max number of starts 30/hour. Min. impeller diameter for duty with low water level or intermittent dry running.

Max impeller diameter requires half motor or more submersed for continuous duty. (Pump can operate lying down.)

Electric motor

3-phase squirrel-cage induction motor, 50 Hz:

Service factor 1.1. Class F insulation.

Motor rating P2: 11.8 kW. 2 pol.

Speed: 2920 rpm.ŋ: 89.8 (50 %), 90.9 (75 %), 90.8 (100 % load)

| Voltage, V |

230 |

400 |

500-550 |

690 |

1000 |

| Nominal current, A |

37.4 |

21.5 |

17.2 |

12.5 |

8.6 |

Starting method and motor protection

XJS 110 AT: Direct on line start (DOL 500-550 V) with built in AquaTronic unit, which automatically adjusts phase order by dual contactors, ensuring correct motor rotation. Soft start (400 V) is built in with the AquaTronic unit, where three thyristors reduces start current to three times the nominal current. Here two relays ensure correct motor rotation. The AquaTronic unit monitors motor temperature, by use of NTC thermistors built into stator windings, and stops the motor at high temperature. It will also stop the motor at high amperage or if a phase is missing.

XJS 110: Direct on line start with built in contactor. Pumps to be used with VFD or 1000 V must have terminal block instead of con-tactor. Thermal switches (140 °C, ±5) built into the stator windings are connected to the contactor and stop the pump at high tempera-ture.

Power cable

20 m type H07RN8-F (standard cable):

4 x 6 sq.mm. (230 V)

4 x 4 sq.mm. (400 V, 500-550 V)

4 x 2.5 sq.mm. (690 V)

20 m type NSSHÖU.../3E (heavy duty cable):

3x6+3x6/3E+3x1.5 (3 control cables included) (230-400 V terminal block)

3x2.5+3x2.5/3E+3x1.5 (3 control cables included) (500-1000 V terminal block)

3x6+3x6/3E+3x1.5 (230-400 V)

3x2.5+3x2.5/3E (500-550 V, 690 V)

Shaft seal

Double mechanical seal in oil bath.

Primary seal: Silicon carbide on silicon carbide.

Secondary seal: Silicon carbide on carbon.

Bearings

Upper bearing: Single-row deep groove ball bearing.

Lower bearing: Double angular contact ball bearing.

Discharge connections

2 ½", 3" (standard), 4" hose connections.

2 ½", 3", 4" G/B.S.P. threaded connections.

Weight

80 kg (without cable)

Options and accessories

AquaPlug. AquaTronic control panel.

Level sensor. Service data kit.

Zinc anodes. Surface protection coating.

Floatation ring. Discharge connection accessories and hose.

Pump control

| |

|

XJS 110 AT |

| Features |

XJS 110 |

AT |

AT + Level Sensor |

AT + AquaPlug / AquaTronic Control Panel |

AT + AquaPlug / AquaTronic Control Panel + Level Sensor |

Service Data Kit Read out |

| Run mode |

X |

X |

X |

X |

X |

|

| Integrated start equipment |

X |

X |

X |

X |

X |

|

| Automatic direction of rotation |

|

X |

X |

X |

X |

|

| Motor protection high temp |

X |

X |

X |

X |

X |

X |

| Motor protection high amp |

|

X |

X |

X |

X |

X |

| Protection against missing phase |

|

X |

X |

X |

X |

X |

| Level control |

|

|

X |

|

X |

|

| Dry run protection |

|

|

X |

|

X |

|

| Automatic restarting |

|

|

X |

|

X |

|

| Stop mode |

|

|

|

X |

X |

|

| E-mode (Automatic stop/run) |

|

|

X |

|

X |

|

| Indication of water in oil |

|

|

|

X |

X |

X |

| Indication of low motor insulation |

|

|

|

X |

X |

X |

| Indication of high or low voltage |

|

|

|

XX |

XX |

X |

| Indication of high temperature |

|

|

|

XX |

XX |

X |

| Indication of high amp |

|

|

|

XX |

XX |

X |

| Indication of phase unbalance |

|

|

|

XX |

XX |

X |

| USB cable connection |

|

X |

X |

X |

X |

X |

| Crash log (10 latest) |

|

|

|

|

|

X |

| Documentation (spare part list, workshop manual) |

|

|

|

|

|

X |

XX = Fault indication when pump is automatically stopped to protect the motor.

Materials

| Description |

Material |

EN |

ASTM |

| Castings |

Aluminium |

EN 1706:AC-43100 |

ASTM AlSi10mg |

| Casing / Jacket |

Stainless steel |

10088:X5CrNi18-10 (1.4301) |

AISI 304 |

| Rotor shaft |

Stainless steel |

10088:X20Cr13 (1.4021) |

AISI 420 |

| Impeller / Wear ring |

White cast iron |

EN-GJN-HV600(XCr23) |

ASTM A 532: Alloy III A |

| Fasteners |

Stainless steel |

10088:X5CrNiMo 17122 (1.4401) |

AISI 316 |

| Wear parts / O-rings |

Nitrile rubber |

|

|

| Coating |

2 component epoxy paint 120 μm |

|

|