Submersible Mixed-Flow Column Pump Type Sulzer AFLX 0600-1200

Sulzer Submersible Mixed Flow Pumps AFLX for Large Volumes at Low to Medium Heads

Sulzer Submersible Mixed Flow Pumps AFLX for Large Volumes at Low to Medium Heads

Features

- For wastewater and sewage containing solid or fibrous matter and for sludges.

- For use in combined rain water and sewage pumping stations, dewatering installations, reclaimed land dewatering and for use in municipal and industrial areas.

- Easy installation in the riser pipe by means of a self centering, self sealing coupling system.

- Easy maintenance thanks to the compact modular unit design.

- Automatic moisture detection and temperature monitoring.

- Newly developed hydraulics with broad band of high efficiencies.

- Available in standard and explosion proof versions.

Application areas

AFLX Submersible pumps can be used everywhere where large volumes of process water or wastewater containing solid effluent must be pumped. Even liquids with fibrous components are no problem for this pump series. The AFLX pumps can be applied as any of the following:

- sewage pumps;

- active sludge pumps;

- combined sewage and surface water pumps;

- drainage pumps in pumping stations for dewatering reclaimed land in low lying coastal areas;

- storm water pumps for storm protection in areas liable to flooding;

- transfer pumps to control the water level in lakes and lagoons subject to tidal influence;

- industrial raw water and process water pumps, pumps for dry docks, canals and harbors cooling;

- pumps in power plants;

- raw water pumps for preparation and supply of drinking water;

- irrigation pumps to allow areas of low rainfall to be used for agricultural and other purposes.

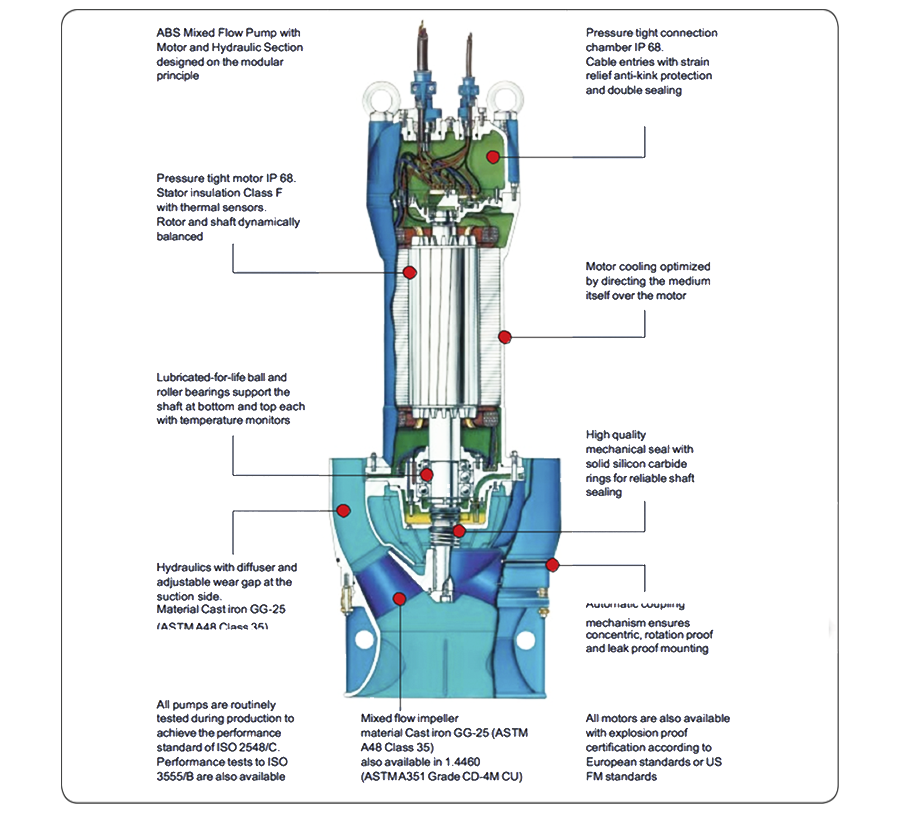

Design

An economical modular system provides for optimum combination of hydraulics and motor to suit the required operating conditions. Compact adaptable construction system.

Motor

In water tight housing, protected to IP 68 and insulation class F with lubricated for life maintenance free bearings and high quality silicon carbide mechanical seal.

The advantage: Reliable and economical running Performance Range.

As an optional extra ABS can supply the required monitoring electronics for installation into the control panel.

Robust shaft construction for many years of operation under constant heavy load. Over dimensioned bearings with grease lubrication is maintenance free.

Your guarantee for a long reliable operating life. Can be supplied in explosion proof form with European Certification or US FM Certification.

Hydraulics

Mixed flow impellers with large free passage ensure blockage-free operation at high efficiencies. Large performance field for practically all applications and excellent efficiencies.

Installation

Suitable for installation in steel or concrete riser pipes for economical operation and simple installation. The centering of the pump and sealing between pump and pipe line is achieved automatically by means of a conical coupling ring.

No additional installation work required.

Maintenance

Easy maintenance and flexibility are the characteristics of the AFLX pumps. Continuous stator, bearing and seal monitoring systems provide effective remote surveillance of these major components.

All bearings are lubricated for life and maintenance free. An oil change is only necessary if the moisture sensor in the oil chamber has activated. Flexibility instead of rigid inspection intervals.

|

Type AFLX DN

|

Motor

|

Weight (kg)

|

H mm

|

I1 mm

|

I2 mm

|

| 600 |

M 185/6-41

M 200/6-42

M 300/6-43

M 150/8-41

М 185/8-42

М 220/8-43

|

415

435

455

410

440

450

|

970

1080

1080

970

1080

1080

|

320

320

320

320

320

320

|

250

250

250

250

250

250

|

| 700 |

M 370/6-51

M 450/6-52

M 550/6-53

M 750/6-54

M 900/6-55

M 150/8-41

M 185/8-42

M 200/8-43

|

820

870

970

1030

1110

525

555

565

|

1335

1335

1485

1485

1575

1025

1135

1135

|

315

315

315

315

315

315

315

315

|

300

300

300

300

300

300

300

300

|

| 800 |

М 750/6-54

М 900/6-55

М 1100/6-61

М 1320/6-62

М 1600/6-71

М 2000/6-72

М 450/8-53

М 550/8-54

М 750/8-55

М 900/8-61

М 1100/8-62

М 1320/8-63

М 1600/8-71

|

1300

1380

1540

1700

1800

1910

1250

1330

1380

1520

1640

1700

1890

|

1500

1600

2320

2460

2480

2480

1500

1500

1600

2320

2460

2460

2480

|

425

425

425

425

425

425

425

425

425

425

425

425

425

|

350

350

350

350

350

350

350

350

350

350

350

350

350

|

| 800 |

М 220/10-51

М 300/10-52

М 370/10-53

М 450/10-54

М 550/10-55

М 750/10-61

М 900/10-62

М 1100/10-71

М 1320/10-72

|

1000

1050

1180

1240

1380

1530

1660

1700

1910

|

1350

1350

1500

1500

1600

2320

2460

2330

2480

|

425

425

425

425

425

425

425

425

425

|

350

350

350

350

350

350

350

350

350

|

| 1200G** |

М 2000/4-71 G

М 2500/4-72 G

М 3000/4-81 G

М 3500/4-82 G

М 4000/4-83 G

М 4500/4-91 G

М 5000/4-92 G

М 5500/4-93 G

М 6000/4-94 G

М 6500/4-95 G

|

3670

3720

3870

4070

4270

4980

5100

5270

5500

6070

|

2395

2545

2575

2675

2815

3045

3045

3165

3275

3425

|

585

585

585

585

585

585

585

585

585

585

|

600

600

600

600

600

600

600

600

600

600

|

| 1200 ** |

М 2000/10-82

М 2500/10-91

М 3000/10-92

М 3500/10-93

М 1600/12-91

М 2000/12-92

М 2500/12-93

М 3000/12-94

|

3700

4420

4800

5500

4170

4470

4930

5640

|

2465

2525

2645

2905

2405

2525

2755

2905

|

585

585

585

585

585

585

585

585

|

600

600

600

600

600

600

600

600

|

|

Type

|

Power Range

|

Number of Poles

|

| AFLX 0600 |

18.5-30kW

15-22kW

|

6-pole

8-pole

|

| AFLX 0700 |

37-90kW

15-22kW

|

6-pole

8-pole

|

| AFLX 0800 |

75-200kW

45-160kW

22-132kW

|

6-pole

8-pole

10-pole

|

| AFLX 1200 |

200-350kW

160-300kW

200-650kW

|

10-pole

12-pole

4-pole*

|