Sulzer submersible sewage pump XFP 105J – 600X

Sulzer submersible sewage pump XFP 105J – 600X

Sulzer submersible sewage pumps, series XFP are suitable for clear and wastewater, for sewage with sludge containing solids and fibrous material.

Construction

- Energy saving premium efficiency motor in accordance with IE3 of IEC 60034-30, exceeding EFF1 of CEMEP regulation.

- The water-tight fully flood-proof motor and the pump section form a compact and robust unit, easy to clean and easy to service.

- Water pressure sealed connection chamber, with two stage cable entry, protected against excessive cable tension and bending.

- Bimetallic thermal sensors in the stator which open at 140 °C.

- Rotor and rotor shaft dynamically balanced, upper and lower bearings lubricated-for-life, maintenance-free.

- Triple shaft sealing.

- Upper and lower sealing by means of a silicon carbide mechanical seal, independent of the direction of rotation.

- Inspection chamber with sensor for moisture protection to indicate water leakage through mechanical seal.

- Option: Blockage- and maintenance-free internal closed looped cooling system.

- Cooling medium: Glycol – water mixture (standard for PE6 range).

- Hydraulic parts with various impeller options: 2-or 3-channel Contrablock, 2-or 3-channel closed or 3-channel skew.

- These pumps are built as standard in ATEX explosion-proof version in accordance with international standards e.g. Ex d IIB T4/ATEX II 2Gk.

Hydraulics

You have the choice of the following hydraulics in the range of DN 100 to DN 600 discharge.

Hydraulics/ Impeller type

| XFP 105J |

CB2 |

XFP 150M |

CB2 |

| XFP 155J |

CB2 |

XFP 151M |

CB2 |

| XFP 205J |

CB2 |

XFP 205M |

CB2 |

| XFP 206J |

CB2 |

XFP 250M |

CH2 |

| XFP 255J |

CB2 |

XFP 305M |

CB2 |

| XFP 305J |

CB2 |

XFP 306M |

CB2 |

| |

|

XFP 351M |

CH3 |

| |

|

XFP 405M |

CB2 |

| |

|

XFP 400R |

CH3 |

| |

|

XFP 500U |

CH3 |

| |

|

XFP501U |

SK3 |

| |

|

XFP 600V |

CH3 |

| |

|

XFP 600X |

SK3 |

CB... = Contrablock, CH...= closed channel, SK...= skew;

last digit (2 or 3) = Number of impeller vanes

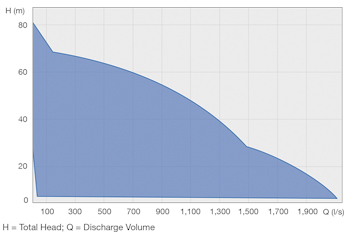

Performance field

Motor

Water pressure sealed premium efficiency motors, (3-phase, squirrel cage induction motors), from 15 to 350 kW and, depending on hydraulic requirements as 4- to 12-pole versions.

Voltage: 380...420 V, 3~, 50 Hz (other voltages on request).

Insulation material: H (motor winding protected by temperature sensor 140 °C).

Temperature rise: According to NEMA class A up to 100kW and class B above.

Protection type: IP68.

Start-up: direct on line (DOL), star-delta, VFD or soft starter.

Standard and options

| Description |

Standard |

Option |

| Max. ambient temperature |

40 °C |

60 °C |

| Max. submergence depth |

20 m |

|

| Mains voltage |

380...420 V/50 Hz |

Other voltage on request |

| Voltage tolerance |

multi-voltage ± 5%; 400 V ± 10 % |

|

| Insulation class |

H (140) |

H (160) (not for explosion-proof) |

| Start-up |

DOL (direct on line), star-delta or soft starter |

|

| Approval |

non-Ex |

Ex/ATEX* |

| Cables |

HO7RNB-F |

EMC shielded cables |

| Cable length |

10 m |

15 m, 20 m, other length on request |

| Mechanical seal (medium side) |

SiC-SiC (NBR) |

SiC-SiC (Viton execution) |

| Mechanical seal (motor side) |

SiC-SiC |

|

| O-rings |

NBR |

Viton |

| Preparation for lifting hoist |

Lifting hoop |

Lifting hoop in stainless steel* |

| Protective coating |

Two component coating epoxy resin |

Special coatings on request |

| Cathodic protection |

|

Zinc anodes on request |

| Installation |

Wet-well |

Dry-well vertical/horizontal |

| Motor cooling |

Cooling by surrounding medium |

Closed loop cooling system** |

| Moisture sensor motor housing/connection chamber |

PE3, PE6 |

PE4, PE5 |

| Moisture sensor inspection chamber |

PE4-PE6 |

|

| Vibration sensor |

|

PE4-PE6 |

* standard for PE3 ** standard for PE6

Motor protection

X = Standard; O = Option; * PTC to be used when operated via VFD ** Not avalable for PE3

|

PE3 to PE6

|

|

Ex

|

Ex VFD drive

|

| Winding |

Bi-metallic switch

Thermistor (PTC)

PT 100

|

X

O

O**

|

X*

O*

O**

|

| Seal protection

|

Inspection chamber

Motor housing

Connection box

|

X**

O (X for PE3 and PE6)

O** (X for PE6)

|

O**

X

O** (X for PE6)

|

|

Temperature bearing

upper/lower

|

Bi-metallic switch

Thermistor (PTC)

PT 100

Vibration sensor

|

O** (X for PE6)

O**

O**

O**

|

O** (X for PE6)

О**

O**

O** |

Materials

|

Motor

|

Standard

|

Option

|

| Connection chamber |

EN-GJL-250 |

|

| Cooling chamber |

EN-GJL-250 |

|

| Cooling jacket |

1.0036 (PE4-PE6)* |

|

| Motor housing |

EN-GJL-250 |

|

| Motor shaft |

1.4021 |

1.4462 |

| Fasteners (medium contacted) |

1.4401 |

|

| Lifting hoop (PE3) |

1.4401 |

|

| Lifting hoop (PE4 & PE5) |

EN-GJS-400-18 |

1.4470 |

| Lifting hoop (PE6) |

1.0553 |

1.4462 |

|

Hydraulics

|

Standard

|

Option

|

| Volute |

EN-GJL-250 |

1.4470 |

| Impeller |

EN-GJL-250 |

1.4470** |

| Bottom plate (only CB version) |

EN-GJL-250 |

1.4470** |

| Shroud (XFP 501U and 600X) |

EN-GJL-250 |

|

| Wear ring (only CH version) |

EN-GJL-300 |

1.4581 |

| Wear ring impeller (only CH version) |

|

1.4571 |

|

Connection sys. (wet)

|

Standard

|

Option

|

| Pedestal |

EN-GJL-250 |

Non sparking |

| Fastening elements |

Stainless steel |

|

| Protective coating |

Epoxy resin based |

|

| Guide rail |

Galv. steel |

Stainless steel |

| Pipe retainer |

EN-GJS-400-18 |

1.4470 |

|

Connection sys. (dry)

|

Standard

|

Option

|

| Support frame |

1.0036 |

Galv. steel |

* PE3=EN-GJL-250 ** or EN-GJL-250 flame hardenend for CB version