Sulzer submersible wastewater pump AS 0530-0841

Sulzer submersible wastewater pump AS 0530-0841

Robust, reliable submersible pumps from 1 to 3 kW for pumping clear water, wastewater and sewage from buildings and sites in domestic and commercial areas in accordance with EN 12056 (AS 0530 – 0841), EN 12050-2 (AS 0530 – 0641), and EN 12050-1 (AS 0830 – 0841).

Applications

AS submersible pumps have been designed for the economic and reliable pumping of wastewater and sewage, and can be used for fixed applications with ABS automatic coupling system or as portable units.

- The 2-inch version is especially suitable for pumping wastewater from underground garages.

- With vortex hydraulics the AS is particularly suitable for fluids containing fibrous or abrasive matter and for sewage.

- The Contrablock hydraulic system is suitable for larger propor- tions of solid or fibrous matter.

- Maximum allowable temperature of the medium is 40 °C, or short term to 60 °C (max. 5 minutes).

Construction

The water pressure-tight, encapsulated fully flood-proof motor and the pump section form a compact, robust, unit construction.

Motor

Single-phase 220-240 V and three-phase 400 V, 50 Hz, 2-pole (2900 r/min) and 4-pole (1450 r/min). Insulation class F; protection type IP 68. Ex protection to Ex d IIB T4 and FM international standards. Consult Sulzer Pumps for Ex usage with frequency inverters.

Bearings

The stainless steel motor shaft is supported in lubricated-for-life ball bearings.

Shaft sealing

Between motor and hydraulic section by means of a high quality sealing unit using a silicon carbide mechanical seal, independent of direction of rotation and resistant to temperature shock. Seal at motor side is by oil lubricated lip seal.

Discharge

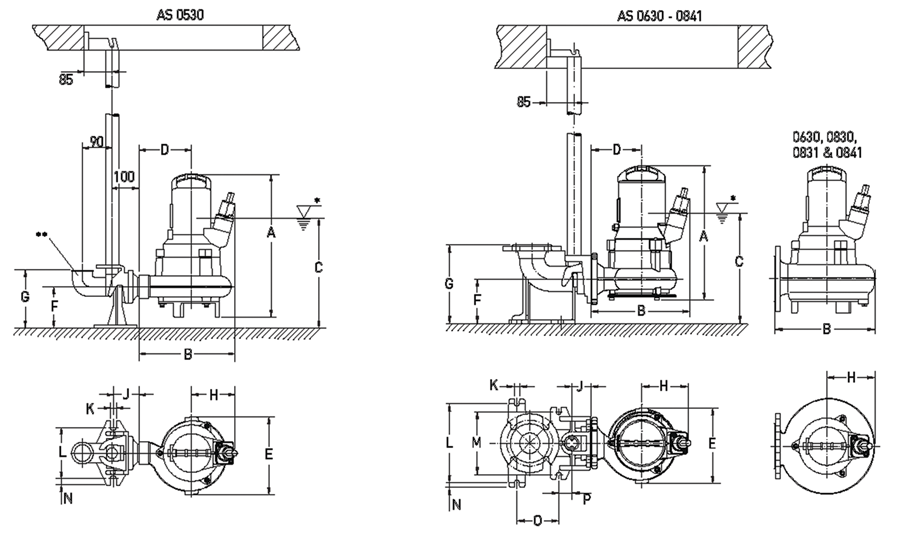

AS 0530: G 2″ internal thread (DN 50)

AS 0630 to 0641: radial slot DN 65 flange

AS 0830, 0831, 0840 & 0841: radial slot DN 80 flange.

Temperature monitoring

TCS (Thermo-Control-System) with thermal sensors in the stator to switch off the pump in the case of overheating and switch on automatically after cooling down (option on standard AS).

Features

- Hydraulic design with Contrablock system or vortex impellers.

- High reliability even under long term operating conditions.

- For wastewater and sewage containing solid or fibrous particles.

- In standard or Ex-versions.

- Option of automatic seal and temperature monitoring. Ex version with temperature monitoring as standard.

- Available for transportable or fixed installation.

Materials

| Description |

Material |

| Motor Housing |

Cast iron EN-GJL-250 |

| Rotor Shaft |

Stainless steel 1.4021 (AISI 420) |

| Volute |

Cast iron EN-GJL-250 |

| Impeller |

Cast iron EN-GJL-250 |

| Bottom plate |

Cast iron EN-GJL-250 |

| Fasteners |

Stainless steel 1.4401 (AISI 316) |

Technical Data

|

AS

|

Solids

size

(mm)

|

Discharge *

|

Rated

voltage

(V)

|

Motor power **

(kW)

P1

|

Motor power **

(kW)

P2

|

Rated

current

(A)

|

Speed

(r/min)

|

Weight ***

(kg)

|

| 530 |

S12/2W(1 |

G 2'' |

220-240 1~ |

1.77 |

1.2 |

8.22 |

2900 |

31 |

| |

S12/2D |

G 2'' |

400 3~ |

1.69 |

1.2 |

3.29 |

2900 |

31 |

| |

S17/2D |

G 2'' |

400 3~ |

2.31 |

1.7 |

3.97 |

2900 |

34 |

| |

S26/2D |

G 2'' |

400 3~ |

3.43 |

2.6 |

5.64 |

2900 |

40 |

| 630 |

S10/4W(1 |

DN 65 |

220-240 1~ |

1.69 |

1 |

7.49 |

1450 |

37 |

| |

S13/4D |

DN 65 |

400 3~ |

1.93 |

1.3 |

3.6 |

1450 |

37 |

| |

S22/4D |

DN 65 |

400 3~ |

2.88 |

2.2 |

5.15 |

1450 |

43 |

| 631 |

S12/2W(1 |

DN 65 |

220-240 1~ |

1.77 |

1.2 |

8.22 |

2900 |

35 |

| |

S12/2D |

DN 65 |

400 3~ |

1.69 |

1.2 |

3.29 |

2900 |

35 |

| |

S17/2W(1 |

DN 65 |

220-240 1~ |

2.36 |

1.65 |

10.6 |

2900 |

35 |

| |

S17/2D |

DN 65 |

400 3~ |

2.31 |

1.7 |

3.97 |

2900 |

35 |

| |

S30/2D |

DN 65 |

400 3~ |

3.74 |

3 |

6.23 |

2900 |

42 |

| 641 |

S30/2D |

DN 65 |

400 3~ |

3.74 |

3 |

6.23 |

2900 |

41 |

| 830 |

S10/4W(1 |

DN 80 |

220-240 1~ |

1.69 |

1 |

7.49 |

1450 |

40 |

| |

S13/4D |

DN 80 |

400 3~ |

1.93 |

1.3 |

3.6 |

1450 |

37 |

| |

S22/4D |

DN 80 |

400 3~ |

2.88 |

2.2 |

5.15 |

1450 |

43 |

| 831 |

S22/4D |

DN 80 |

400 3~ |

2.88 |

2.2 |

5.15 |

1450 |

45 |

| 840 |

S12/2W(1 |

DN 80 |

220-240 1~ |

1.77 |

1.2 |

8.22 |

2900 |

33 |

| |

S12/2D |

DN 80 |

400 3~ |

1.69 |

1.2 |

3.29 |

2900 |

33 |

| |

S17/2D |

DN 80 |

400 3~ |

2.31 |

1.7 |

3.97 |

2900 |

33 |

| |

S26/2D |

DN 80 |

400 3~ |

3.43 |

2.6 |

5.64 |

2900 |

39 |

| 841 |

S13/4D |

DN 80 |

400 3~ |

1.93 |

1.3 |

3.6 |

1450 |

41 |

| |

S22/4D |

DN 80 |

400 3~ |

2.88 |

2.2 |

5.15 |

1450 |

56 |

Seal monitoring

DI system consisting of a sensor in the motor and oil chambers which signals an inspection alert if there is leakage at the shaft seals (option on standard AS; not in oil chamber on Ex version).

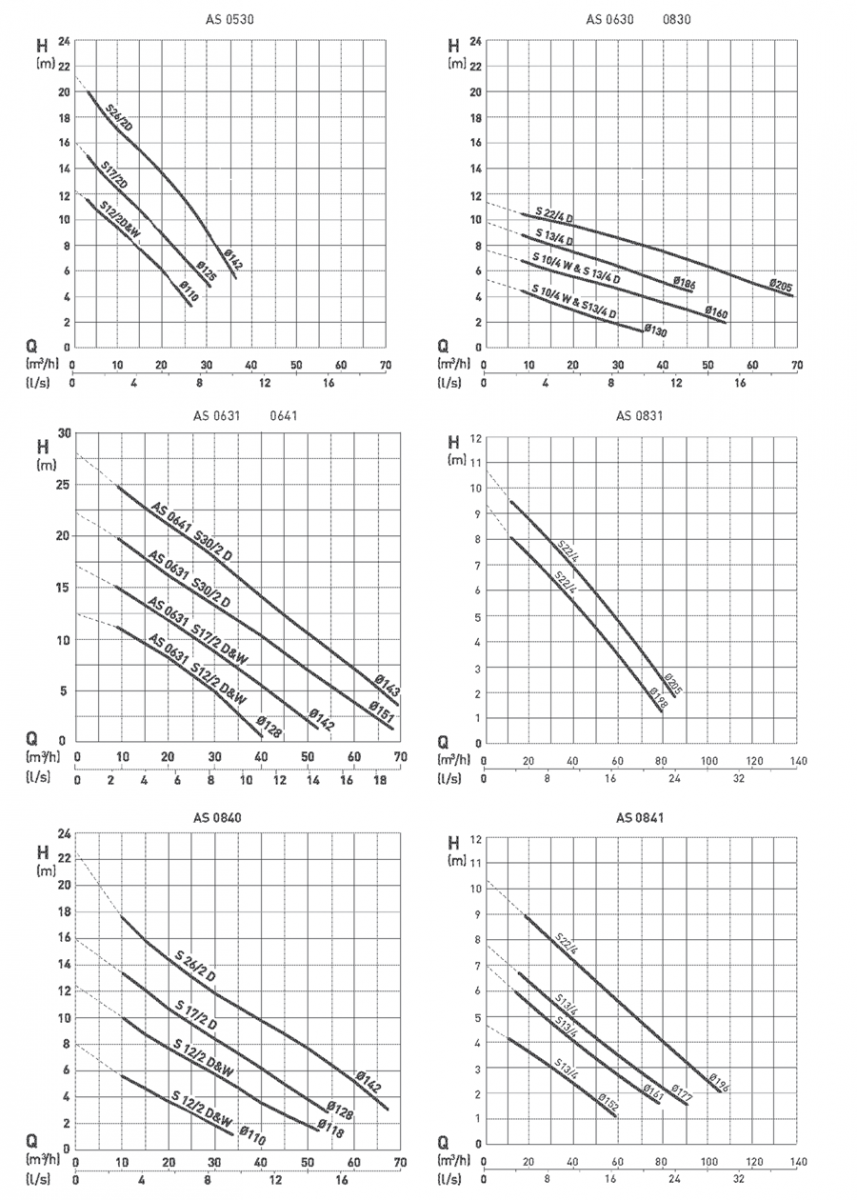

Hydraulics

AS 0530, 0630, 0631, 0830, 0831: vortex, open, recessed four-vane impeller.

AS 0641, 0840, 0841: Contrablock, open single-vane impeller with spiral bottom plate.

* G = internal thread, DN = flange

** P1 = Power at mains; P2 = Power at motor shaft;

*** Weight with 10 m cable.

Cable size: Standard = 4G1.5, Ex = 7G1.5 (1 Start and Run capacitor to the following specification required in control panel).

Start: 125-160µF.

Run: 40µF (2×20µF) for S10/4W, 30µF for S12/2W & S17/2W

The recommended start time for the motors is two seconds.

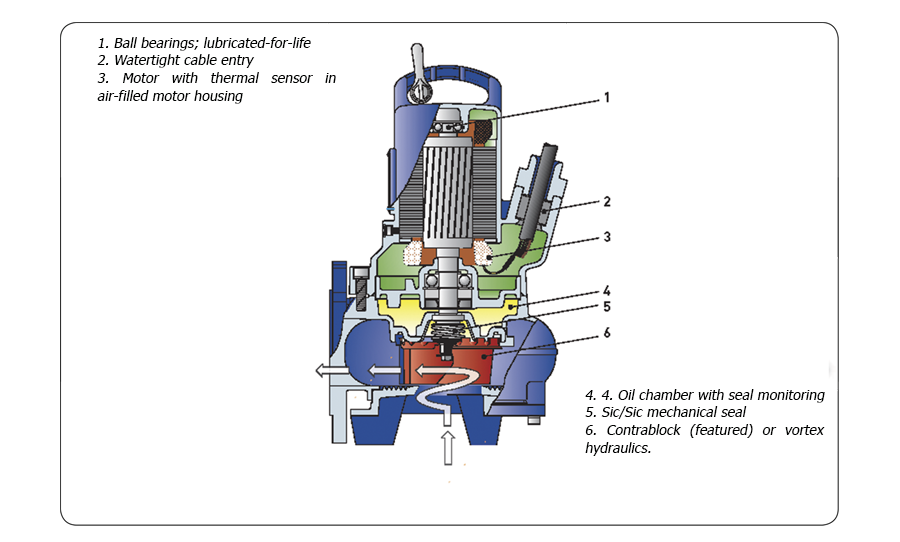

Design

1. Ball bearings; lubricated-for-life

2. Watertight cable entry

3. Motor with thermal sensor in air-filled motor housing

4. 4. Oil chamber with seal monitoring

5. Sic/Sic mechanical seal

6. Contrablock (featured) or vortex hydraulics.

Accessories

| |

Description

|

Size

|

Part no.

|

AS

|

|

Fixed installationwith ABS

AutomaticCoupling System

|

Pedestal (cast iron EN-GJL-250)

threaded (with fixing bolts and

transition piece)flange (with fixing

bolts)flange (with fixing

bolts)flange (fixing bolts not

included)flange (with plug/

clamp connectionand fixing bolts)

|

2" without bend

DN 65: 90º cast bend

DN 80 without bend

DN 80: 90º cast bend

DN 80: 90º cast bend

|

62320560

62320673

62320557

62320649

62320650

|

0530

0630-0641

0830 & 0840

0830/31/40/41

0830/31/40/41

|

|

|

Fasteners (galvanized steel)bolts and

gasket (bracket to pump)

anchor bolts (pedestal to base)

|

|

62610632

62610775

|

0830/31/40/41

0830/31/40/41

|

|

|

Guide Rail (galvanized steel)

|

1¼” x 1 m

1¼” x 2 m

1¼” x 3 m

1¼” x 4 m

1¼” x 5 m

|

31380007

31380008

31380009

31380010

31380011

|

0530-0641

|

|

|

Chain Kit (galvanized steel)

|

3 m

4 m

6 m

7 m

|

61265065

61265093

61265069

61265096

|

0530-0841

|

|

|

Chain Kit (stainless steel)

|

3 m

4 m

6 m

7 m

|

61265081

61265099

61265085

61265102

|

0530-0841

|

|

Fixed installation

-dry well: (horizontal)

|

Pump Support Kit (EN-GJL-250)

headand volute supports

withfixing boltsand vibration damper

|

|

61825001

|

0831 & 0841

|

| (vertical) |

Ground Support Stand |

|

61355002 |

0831 & 0841 |

|

Transportableinstallation

|

Ground Support Stand

|

|

42895016

61355012

61350526

|

0630 & 0830

0631 & 0641

0831 & 0841

|

| |

Discharge Elbow (EN-GJL-250)flangeto threadflange to STORZ coupling |

DN 80 to G 2½"

DN 80 to G 2½"

|

31090131

62665074

|

0840 |

| |

Adaptor (galvanized steel) |

DN 65 to DN 80 |

21405002 |

0630 & 0631 |

|

General

|

Non-return Ball Valve

(EN-GJL-250)

internal threadinternal thread

with inspection hatchflange

with inspection hatch and

ventingflange with

inspection hatch

|

G 2"

G 2½"

DN 80

DN 80

|

61400527

61400543

61400534

61400523

|

0530

0630-0641

0830/31/40/41

0830/31/40/41

|

|

|

Gate Valve (brass)(EN-GJL-250)

|

G 2"

DN 80

|

14040007

61420500

|

0530

0830, 0831,

0840 & 0841

|