Sulzer Piranha submersible grinder pump 08-110

Sulzer Piranha submersible grinder pump 08-110

Sulzer submersible pumps Piranha for problem-free pumping of sewage containing faecal matter in pipe lines from 1¼” (DN 32) in accordance with EN 12050-1.

Applications

Piranha submersible pumps have been designed for effective and economic dewatering using discharge lines of small diameter, in private, municipal and industrial areas.

- Sewage removal from living units and houses in remote settlements where the laying of a conventional sewer would be too expensive, where large ground undulations are present or where it is only possible to lay pipe lines of small diameter.

- Sewage removal from motorway resting sites, communal buildings and for renovation of buildings or areas of a city.

- For use in slaughter houses, food processing plants, paper factories, agriculture and similar areas.

- Piranha 08 and 09 are specially designed for private and domestic applications.

- Maximum allowable temperature of the medium is 40 °C, or short term to 60 °C (max. 5 minutes)

Construction

The water pressure tight, encapsulated fully flood-proof motor and the pump section form a compact, robust, unit construction.

Bearings

The stainless steel motor shaft is supported in lubricated-for-life ball bearings.

Shaft sealing

Of a high quality sealing unit using a silicon carbide mechanical seal. Seal at motor side is by oil lubricated lip seal.

Piranha PE30/2C – 110/2E: Double mechanical seals, SiC-SiC at the hydraulic side, SiC-C at the motor.

All seals are independent of direction of rotation and resistant to temperature shock.

Discharge

Piranha 08 and 09: DN 32 flange with G 1¼” internal thread Piranha S10 – S26 and PE30/2C: DN 32 flange (G 1¼” threaded adaptor available as accessory). Piranha PE55/2E – PE110/2E: DN 50 with DIN-flange.

Seal monitoring

DI system consisting of a sensor in the motor and oil chambers which signals an inspection alert if there is leakage at the shaft seals (not in oil chamber on Ex Piranha-S). Not available for Piranha 08 and 09; optional for non-Ex Piranha-S.

Shredding system

Spiral bottom plate and stationary cutter ring combined with a shredding rotor located before the impeller, for optimum blockage-free running.

Features

- Unique ABS Piranha shredding system capable of shredding items such as cloths and plastic bags.

- For the pumping of wastewater containing sewage, offal, organic and industrial effluent.

- Piranha 08 and 09 fitted with MF modular motor; Piranha-S with AS, Piranha PE with XFP Premium Efficiency IE3.

- Piranha 08 and 09 available as KS version with float switch.

- Small discharge lines from 1¼” (DN 32).

- Installations are possible where large ground undulations are present.

- Standard and Ex-versions (see motor data below).

- Piranha 08 and 09 have capacitor in upper lid and do not require a control box.

- Low installation costs due to small diameter discharge pipe- work.

Motor

Three-phase 400 V or single-phase 220-240 V, 50 Hz, 2-pole (2900 r/min) or 4-pole (1450 r/min).

Cooled by amply dimensioned cooling areas.

Piranha 08 & 09: insulation class F, protection type IP 68, non-Ex only.

Piranha S10 – S26: insulation class F, protection type IP 68, Ex and non-Ex.

Piranha PE30/2C – PE110/2E: Premium Efficiency IE3 with NEMA Class A temperature rise, insulation class H, protection type IP 68, Ex only.

Explosive-proof versions are in accordance with EX d IIB T4 and ATEX international standards.

Temperature monitoring

Thermal sensors in the stator to switch off the pump in the case of overheating and switch on automatically after cooling down (optional for non-Ex Piranha-S model).

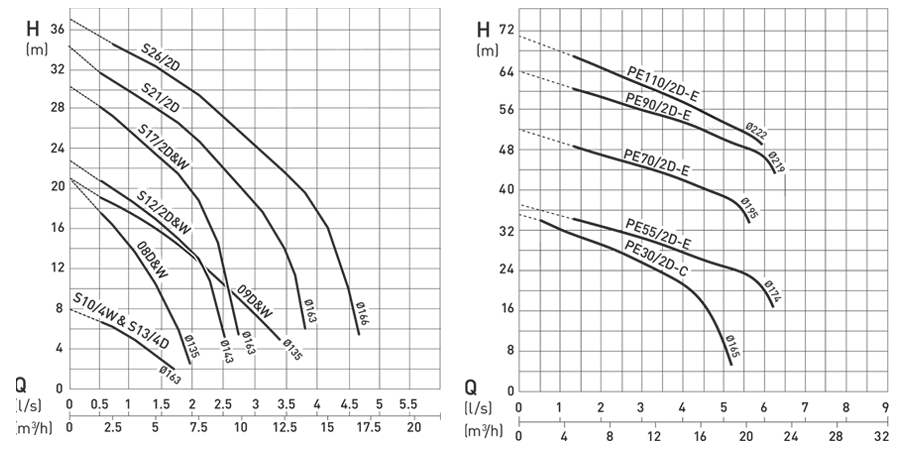

Technical Data

|

Piranha

W = 1-phase

D = 3-phase

|

Discharge

Flange

DN

|

Discharge

Internal

thread *

|

Motor power **

(kW)

P1

|

Motor power **

(kW)

P2 |

Rated

current

(A)

|

Rated

voltage

(V)

|

Speed

(r/min)

|

Cable

size ***

|

Weight ****

(kg)

|

| 08W |

- |

G 11/4'' |

1.41 |

1 |

6.41 |

220-240 1 ~ |

2900 |

3G1.0 |

18 |

| 08D |

- |

G 11/4'' |

1.34 |

1 |

2.71 |

400 3~ |

2900 |

4G1.0 |

18 |

| 09W |

- |

G 11/4'' |

2.56 |

1.84 |

11.6 |

220-240 1 ~ |

2900 |

3G1.0 |

23 |

| 2309D |

- |

G 11/4'' |

2.56 |

2 |

4.64 |

400 3~ |

2900 |

4G1.0 |

23 |

| S10/4 W(1 |

32 |

G 11/4'' |

1.69 |

1 |

7.49 |

220-240 1 ~ |

1450 |

4G1.0 |

32 |

| S12/2 W(1 |

32 |

G 11/4'' |

1.77 |

1.2 |

8.22 |

220-240 1 ~ |

2900 |

4G1.0 |

32 |

| S12/2 D |

32 |

G 11/4'' |

1.69 |

1.2 |

3.29 |

400 3~ |

2900 |

4G1.0 |

32 |

| S13/4 D |

32 |

G 11/4'' |

1.93 |

1.3 |

3.6 |

400 3~ |

1450 |

4G1.0 |

32 |

| S17/2 W(1 |

32 |

G 11/4'' |

2.36 |

1.65 |

10.6 |

220-240 1 ~ |

2900 |

4G1.0 |

32 |

| S17/2 D |

32 |

G 11/4'' |

2.31 |

1.7 |

3.97 |

400 3~ |

2900 |

4G1.0 |

32 |

| S21/2 D |

32 |

G 11/4'' |

2.79 |

2.1 |

4.75 |

400 3~ |

2900 |

4G1.0 |

37 |

| S26/2 D |

32 |

G 11/4'' |

3.43 |

2.6 |

5.64 |

400 3~ |

2900 |

4G1.0 |

40 |

| PE30/2C D |

32 |

G 11/4'' |

4.58 |

4.02 |

6.32 |

400 3~ |

2900 |

7G1.5 |

|

| PE55/2E D |

50 DIN |

|

6.08 |

5.5 |

10.3 |

400 3~ |

2900 |

10G1.5 |

130 |

| PE70/2E D |

50 DIN |

|

7.74 |

7 |

13.5 |

400 3~ |

2900 |

10G1.5 |

130 |

| PE90/2E D |

50 DIN |

|

9.39 |

8.5 |

16 |

400 3~ |

2900 |

10G1.5 |

145 |

| PE110/2E D |

50 DIN |

|

12.1 |

11 |

20.1 |

400 3~ |

2900 |

10G1.5 |

145 |

* Piranha 08 and 09 flange has internal thread. Piranha S10/4 - S26/4 and Piranha PE30/2D-C has threaded flange adaptor as optional accessory

** P1 = Power at mains; P2 = Power at motor shaft

*** Piranha S10/4 Ex and Piranha S10 /4- S26/2 with Di and klixon: 7G1.5 **** Weight with 10 m cable

(1 Start and Run capacitor to the following specification required in control panel.

Start: 125-160μF

Run: 40μF (2x20μF) for S10/4W, 30μF for S12/2W and S17/2W

The recommended start time for the motors is two seconds.

Materials

| Description |

Material |

| Upper Lid * |

Stainless steel 1.4301 (AISI 304) |

| Motor Housing |

Cast iron EN-GJL-250 |

| Rotor Shaft |

Stainless steel 1.4021 (AISI 420) |

| Volute |

Cast iron EN-GJL-250 |

| Impeller ** |

Cast iron EN-GJL-250 |

| Fasteners |

Stainless steel 1.4401 (AISI 316) |

* Piranha 08 and 09

** Polyamide for Piranha 08

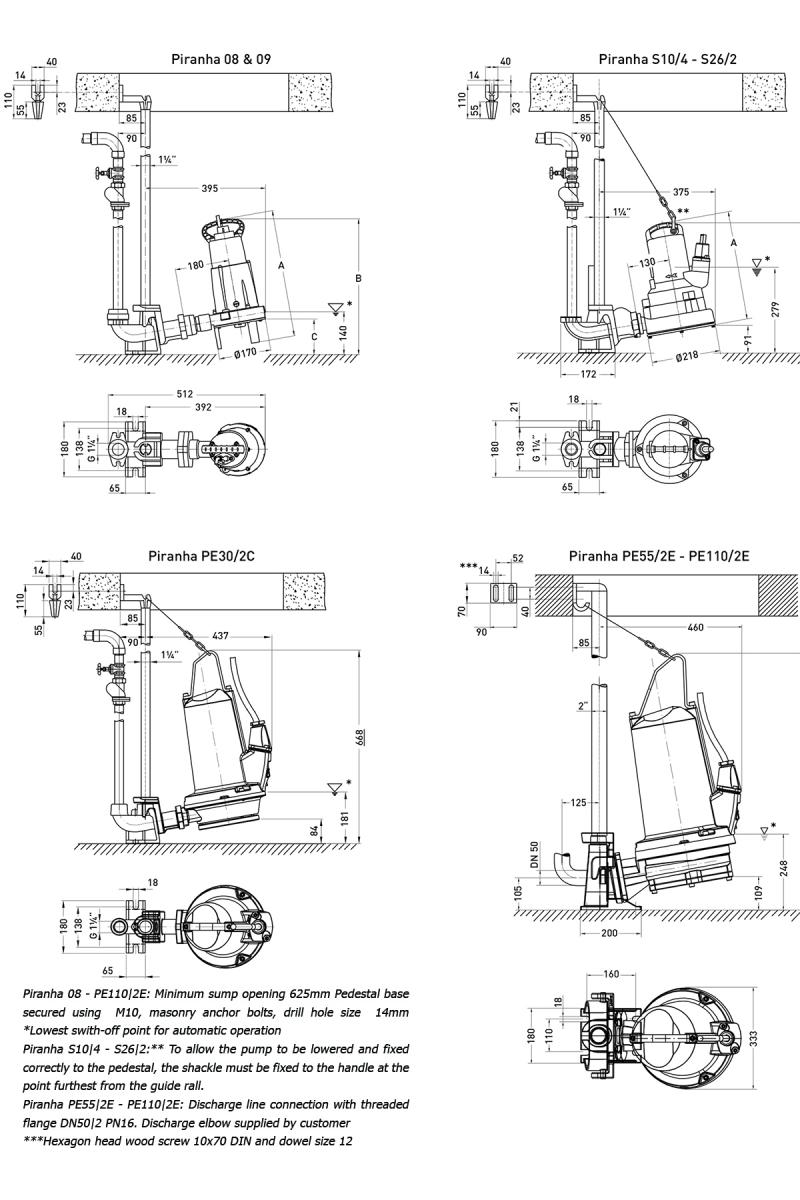

| Piranha |

A |

B |

C |

| 08 |

420 |

445 |

117 |

| 09 |

445 |

470 |

108 |

| S10/4-S17/2 |

347 |

414 |

- |

| S21/2 & S26/2 |

360 |

427 |

- |

| PE 55/2E - PE 90/2E |

- |

774 |

- |

| PE110/2E |

- |

844 |

- |

Accessories

| |

Description |

Size |

Part no. |

Piranha |

|

Fixed installation

with pedestal

|

Pedestal (EN-GJL-250)

90º cast bend

|

G 11/4''

G 11/4''

G 11/4''

|

62325007

62320674

62320676

|

08 и 09

S10-S26

PE30-2C

|

|

|

90º cast bend with built-in

non-return valve without bend

|

G 11/4''

G 11/4''

DN50/G2''

|

62320536

62320538

62320660

|

S10-S26

PE30-2C

PE55/2E-110/2E

|

|

|

Threaded Adaptorhexagon

double nipple

|

G 1¼"

|

13770011

|

08 & 09

|

|

|

Guide Rail (galvanized steel)

|

1¼” x 1 m

1¼” x 2 m

1¼” x 3 m

1¼” x 4 m

1¼” x 5 m

|

31380007

31380008

31380009

31380010

31380011

|

08-S26

PE30/2C

|

|

|

Chain Kit (galvanized steel)

including shackle

|

3m

4m

6m

7m

|

61265065

61265093

61265069

61265096

|

08-PE110/2E

|

|

|

Chain Kit (stainless steel)

including shackle

|

3m

4m

6m

7m

|

61265081

61265099

61265085

61265102

|

08-PE110/2Е

|

|

Transportable

applications

|

Threaded Flange Kit

(EN-GJL-250)including

discharge piece, gasket and bolts

|

G 11/4''

|

61180512

|

S10-PE30/2C

|

|

|

Ground Support Stand (St. 37)

with fixing bolts

|

|

61900013

61900007

|

S10/4-S26/2

PE30/2C-110/2E

|

|

|

Fixed Coupling (brass) GEKA

with external thread

|

G 11/4''

|

15020003

|

S10-PE30/2C

|

|

|

Hose Coupling

with nozzle, outer dia. 34 mm

|

G 11/4''

|

15020018

|

S10-P30/2C

|

|

Horizontal

(tank connection)

|

Pump

with built-in flange on suction side

|

DN 150/PN 16 до

DIN 2633

|

по запросу

|

S10-PE110/2E

|

|

|

Head Support (EN-GJL-250)

with vibration damping

|

|

62665103

41425005

|

S10-P30/2C

PE55/2E-110/2E

|

|

General

|

Non-return Valve (EN-GJL-250)

ball valve with internal thread

|

G 11/4''

G 11/2''

G2''

|

61400525

61400526

61400527

|

08-PE110/2E

|

|

|

Shut-off Valve (brass)

with internal thread

|

G 11/4''

G 11/2''

G2''

|

14040005

14040006

14040007

|

08-PE110/2E

|