Sulzer submersible sewage pump XFP PE7

Sulzer submersible sewage pump XFP PE7

Sulzer Submersible sewage pump type XFP PE7 is designed for municipal

and industrial wastewater equipped with Premium Efficiency

IE3-level motor. Suitable for clean water and wastewater, sewage

with fibrous material and high contain of rags, solids and sludge.

Construction

- Premium Efficiency IE3 motors in accordance with IEC 60034-30.

- Tested in accordance with IEC60034-2-1.

- Premium Efficiency motors designed for VFD operation in accordance with IEC/TS 60034-25 A (Upeak< 1300 V).

- The water-tight fully flood-proof motor and the pump section form a compact and robust unit, easy to clean and easy to service.

- Water pressure sealed connection chamber, with two stage cable entry, protected against excessive cable tension and bending.

- Insulation system: Class H.

- Thermal protection sensors in the stator which open at 140 °C.

- Rotor and shaft dynamically balanced.

- Upper and lower bearings lubricated-for-life, maintenance-free.

- Insulated upper bearing for VFD operation.

- Triple shaft sealing.

- Upper mechanical seal from SiC/SiC and lower mechanical seal from SiC/SiC, independent of the direction of rotation.

- Inspection chamber with sensor for moisture protection to indicate water leakage through mechanical seal.

- Blockage-free open cooling system. Cooled by the medium.

- Impeller types: 2-or 3-channel closed, skew- or mixed flow impeller.

- Option: Available in ATEX explosion-proof* version in accordance with international standards e.g. ATEX II 2G Ex db IIB T4 Gb, FM see table “Motor power and pole overview”.

Hydraulics

You have the choice of the following hydraulics in the range of DN 350 to DN 800 discharge. For power demand beyond avalable range, please refer to technical data sheet XFP CB-Plus or XFP 105J-800X.

Hydraulics/ Impeller type

| XFP 355V |

CH2 |

XFP 600V |

CH3 |

| XFP 400T |

CH3 |

XFP 600X |

SK3 |

| XFP 500U |

CH3 |

XFP 800X |

MX5 |

| XFP 505V |

CH2 |

XFP 801X |

CH5 |

CH...= closed channel, SK...= skew;

last digit (2 or 3) = Number of impeller vanes

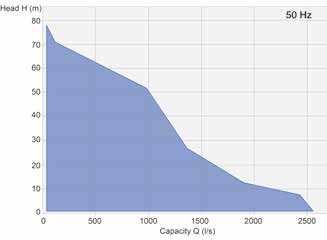

Performance field

Motor

| Pole |

Motor Power P2 in kW (50 Hz) |

| 6 |

250* |

300* |

350* |

400 |

450 |

500 |

550 |

| 8 |

160* |

200* |

250* |

350 |

350 |

400 |

450 |

| 10 |

160* |

200* |

250 |

350 |

350 |

|

|

| 12 |

160 |

200 |

250 |

|

|

|

|

* available in ATEX

Standard and options

| Description |

Standard |

Option |

| Max. ambient temperature |

40 °C |

60 °C |

| Max. submergence depth |

20 m |

|

| Mains voltage |

380...420 V/50 Hz |

Other voltage on request |

| Voltage tolerance |

multi-voltage ± 5%; 400 V ± 10 % |

|

| Insulation class |

H (140) |

H (160) non ATEX |

| Start-up |

DOL (direct on line), VFD or soft starter |

star-delta |

| Approval |

non-Ex |

Ex/ATEX according to table "Motor power and pole overview" |

| Cables |

HO7RNB-F |

EMC shielded cables |

| Cable length |

10 m |

15 m, 20 m, other length on request |

| Mechanical seal (medium side) |

SiC-SiC (NBR) |

SiC-SiC (Viton execution) |

| Mechanical seal (motor side) |

SiC-SiC (NBR) |

|

| O-rings |

NBR |

Viton |

| Preparation for lifting hoist |

Lifting hoop |

|

| Protective coating |

Two component coating epoxy resin |

Special coatings on request |

| Cathodic protection |

|

Zinc anodes on request |

| Installation |

Wet-well |

Dry-well vertical/horizontal |

| Motor cooling |

Blockage-free open cooling system |

|

| Moisture sensor motor housing |

DI (sensor for moisture detection) |

|

| Moisture sensor connection chamber |

DI (sensor for moisture detection) |

|

| Moisture sensor inspection chamber |

DI (sensor for moisture detection) |

|

| Vibration sensor |

|

on request |

Motor protection

X = Standard; O = Option; * PTC to be used when operated via VFD

|

PE7

|

|

non-Ex

|

Ex / ATEX

|

| Winding |

Bi-metallic switch

Thermistor (PTC)

PT 100

|

X

O

O

|

X*

O*

O*

|

| Seal protection

|

Inspection chamber

Motor housing

Connection box

|

X

X

X

|

X

X

X

|

|

Temperature bearing

upper/lower

|

Bi-metallic switch

Thermistor (PTC)

PT 100

|

X

O

O

|

X

О

O

|

|

Vibration sensor

|

0-20 mm/s

|

O

|

O |

Materials

|

Motor

|

Standard

|

Option

|

| Connection chamber |

EN-GJL-250 |

|

| Cooling chamber |

EN-GJL-250 |

|

| Cooling jacket |

1.0036 |

|

| Motor housing |

EN-GJL-250 |

|

| Motor shaft |

1.4021 |

1.4462 |

| Fasteners (medium contacted) |

1.4401 |

|

| Lifting hoop |

1.0553 |

1.4462 |

|

Hydraulics

|

Standard

|

Option

|

| Volute |

EN-GJL-250 |

1.4470 |

| Impeller |

EN-GJL-250 |

1.4470 |

| Bottom plate |

EN-GJL-250 |

1.4470 |

|

Connection sys. (wet)

|

Standard

|

Option

|

| Pedestal |

EN-GJL-250 |

Non sparking |

| Fastening elements |

Stainless steel |

|

| Guide rail |

Galv. steel |

Stainless steel |

| Pipe retainer |

EN-GJS-400-18 |

1.4470 |

| Protection coating |

Epoxy resin based |

|

|

Connection sys. (dry)

|

Standard

|

Option

|

| Support frame |

1.0036 |

Galv. steel |