Sulzer Scaba Top-Mounted Vertical Agitator

Applications

The Sulzer Scaba agitators are individually tailored for all applications wherever a liquid is to be mixed with another liquid, particles or gas.These agitators are used in wastewater applications, process industry and paper industry.

Design

The agitators are of a robust, modular design and can be combined with various types of drive units, seals and impellers. Due to this flexibility, the agitators can be adapted optimally to the needs of the process.

Drive units

The drive unit selected is determined by the process requirement and the customer’s wishes. The agitator can be equipped with gears, parallel shaft gears, bevel or V-belt drives.

Pedestal module

The pedestal module is equipped with a double spheri-cal roller bearing with adapter sleeve. For a V-belt drive and certain special applications, an extra shaft bearing is built into the pedestal module.

Housing for shaft seal

The housing for the shaft seal is equipped with a suitable seal. The connecting flange of the housing can be sup-plied in different sizes.

Shaft seal

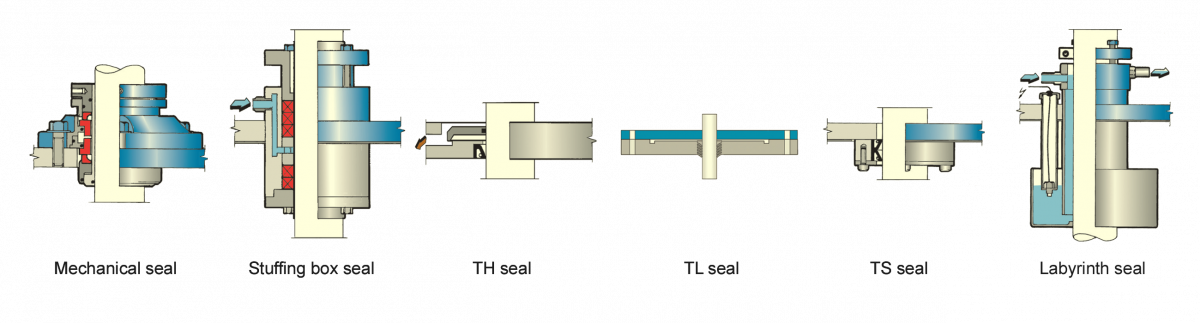

The shaft seals are designed to maintain the required pressure in the tank or to prevent leakage through the shaft entry. Seals are also used to prevent impurities from entering the tank, or to prevent damage to the agi-tator by splashing or by vapour from the process liquid.The shaft seals options are single or double mechani-cal seals, stuffing box, TH, TL and TS seals and labyrinth seal.

Properties

| Propeller diameter |

100mm - 6m (4-236 inches) |

| Power up to |

250kW (335 hp) |

| Shaft length up to |

30m (100 ft) |

Shaft coupling

The agitator is equipped with one or more shaft couplings, if necessary. The couplings are of flange type, although if the hygienic requirements are strict, threaded shaft couplings can be supplied instead.

Agitator impeller

Sulzer has a wide range of patended agitator impellers which are selected to suit specific applications.Combined with our extensive know-how, these im-pellers produce the best possible process results at the lowest possible energy cost.

Motor

Power ratings: 0.12-250kW. The options are electric motors

Shaft seals

Mechanical seal

- Double or single design

- Dry or liquid lubricated

- Split seal

- Liquid-cooled seal housing

- Cartridge seal

Stuffing box seal

The lantern ring, usually included, serves as a gliding bearing and increases the useful life of the seal.The shaft is often equipped with a wear sleeve.

- 5 packing plaits.

- Liquid or grease lubricated.

TH seal

Hygienic seal designed to prevent the ingress of oil and impurities into the process liquid.

TL seal

Protects the agitator from splashing.Complete in PTFE without rubber details.Particularly suitable in areas with aggressive media where rubber details is im-propriate.

TS seal

Lip seal designed to prevent the ingress of impurities into the process liquid.Protects the agitator from splashing.

Labyrinth seal

Seal for low-pressure proc-esses. Particularly suitable for digesters. The height of the water trap is determined by the pressure inside the tank. Can be equipped with level control in the labyrinth

Impellers

SHP1

Our high-flow propeller which is acknowledged for its en-ergy-efficiency and effective-ness.It is just as effective on difficult suspensions and re-actions as it is on homogeniz-ing and mixing. Intended for viscosities up to 50 000 mPas

SHP18

A registred-design develop-ment of the SHP1.Offers better effective-ness at lower viscosities. Low weight allows for lighter shaft design.

SHPD

Double-acting propeller for high viscosities, up to paste consistency. Also suitable for very gentle stirring. Due to the double-acting function, the liquid is pumped both down-wards and upwards.

SRGT

Patended turbine intended for gas dispersion. Due to its design, the power demand is constant at varying gas flows. Performs very well also on three-phase systems com-prising liquid - gas - particles.

Other agitator elements

Our range also includes im-pellers of conventional type.